Global Brewery increases OEE by 5% with actionable insights from Parsable

COMPANY BACKGROUND

This leading global brewery has a large portfolio of beer and other beverage brands, including soft drinks, water and wine. With more than 40,000 employees, its products are sold in more than 150 markets around the world.

THE CHALLENGE

As the company was focused on product development, it meant adopting digital transformation processes took a back seat. One of the biggest concerns was how to easily and quickly enable operators on the floor to complete autonomous maintenance tasks, like clean/inspect/lubricate (CIL).

The brewery had industry-standard CIL steps documented on laminated sheets of paper. They were rarely used and contained outdated images and information. There was no way to track if operators were completing the process or not – the data on CIL completion rates across teams and machines was inadequate. This resulted in a lack of confidence that the machines were being maintained at an optimal level and the inability to accurately track the completion of this critical procedure.

SUCCESS CRITERIA

- Digital workflows for CIL procedures.

- Actionable insights and quick visibility into all CIL jobs.

- Near real-time data collection during CIL operations using a intuitive and versatile tool

THE SOLUTION

With Parsable’s Platform, a line worker can open a CIL job in the mobile app and follow clear instructions that contain interactive rich-media – inline videos, photos, GIFs and PDFs – on how to complete the task correctly.

For operators performing a routine CIL inspection, they can log details of an equipment issue into Parsable’s mobile app and immediately share the information with a line leader or maintenance personnel.

Supervisors have a real-time view into what is happening, and are able to provide a response to triage the issue.

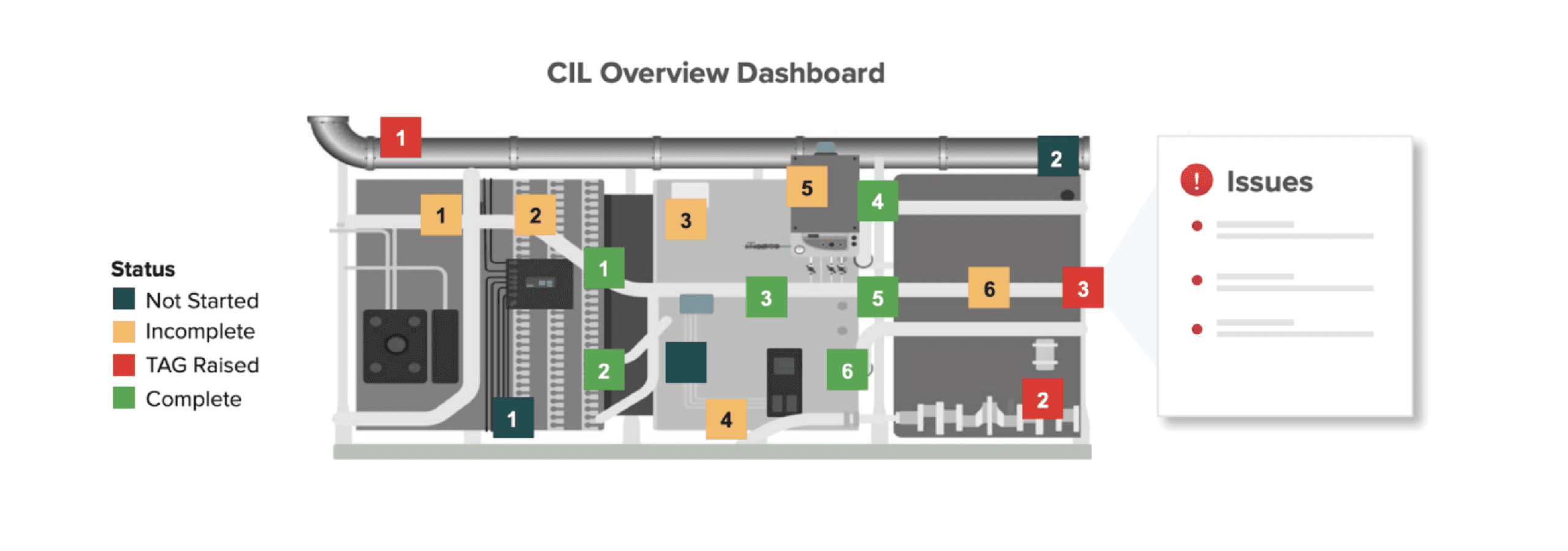

Management is able to see a summary of all CIL jobs in easy-to-understand dashboards. They can even hover over a specific station to see the status of a CIL, the time it was completed, how long it took and whether there were any issues raised. These insights can be viewed across machines and locations.

THE RESULTS

Calculated OEE improvements of 5%

Calculated OEE improvements of 5% Reduced unplanned stoppages, which led to greater maching efficiency

Reduced unplanned stoppages, which led to greater maching efficiency Identified additional hot spots on machines that needed to be maintained

Identified additional hot spots on machines that needed to be maintained