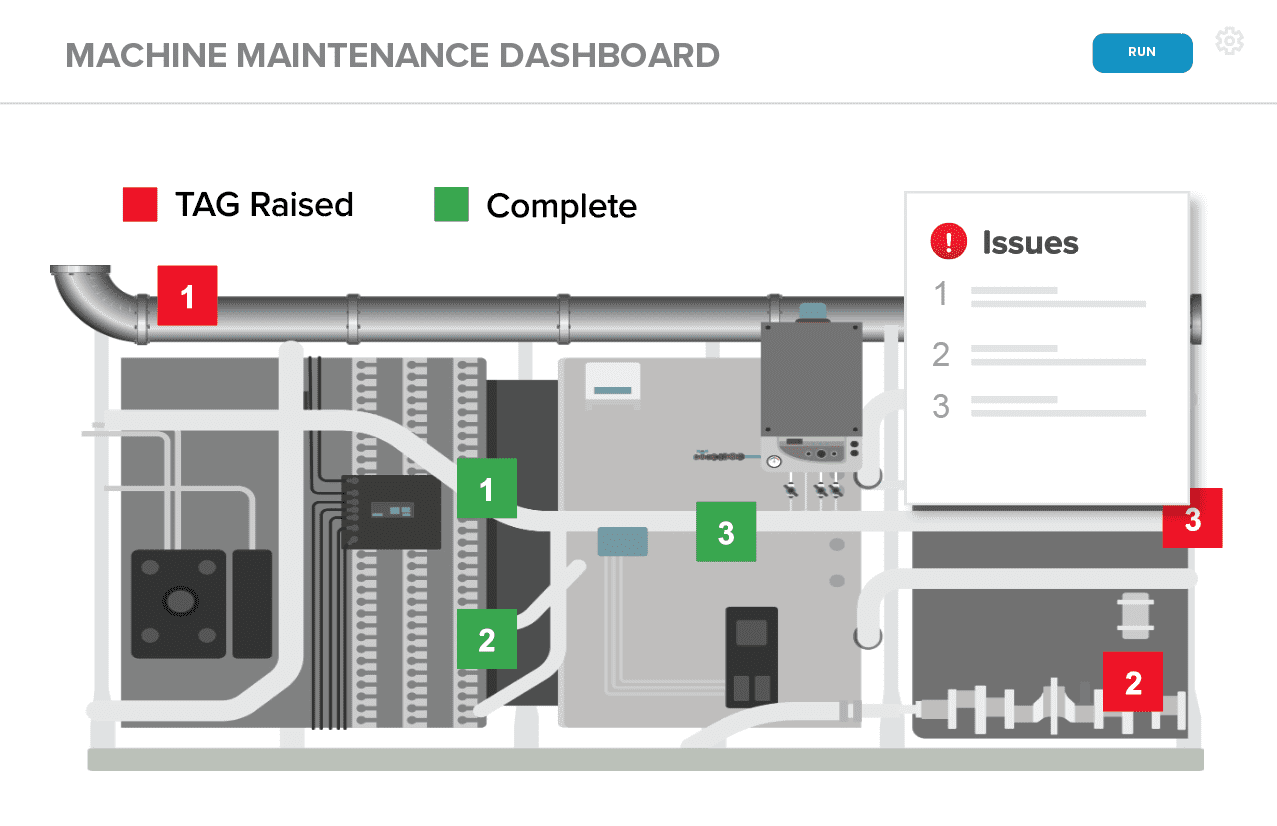

Better visibility offers greater efficiencies

Current systems and hardware can record the “what” and “when” of machine errors and deviations, but they don’t tell you the “why.” With Connected Worker by Parsable, you can capture detailed metadata about the work performed leading up to the error or breakdown, like what steps were done out of order or why equipment was maneuvered in a specific way.

With this new visibility, maintenance teams can dynamically update SOPs to reduce technician error and improve planned maintenance traceability. It enables even small, incremental changes to be made on the floor, resulting in a culture of continuous improvement where every worker is empowered to make a positive difference.