How is Parsable helping global manufacturers drive ESG efforts across plants?

Manufacturers face increasingly strict environmental regulations, a heightened need for safer frontline working conditions, increasing non-compliance fines, and a growing demand from employees, customers and investors to deliver on sustainability initiatives. Yet most lack a technology platform that provides visibility, traceability, and actionable plant-level data and insights to gather and measure their ESG goals.

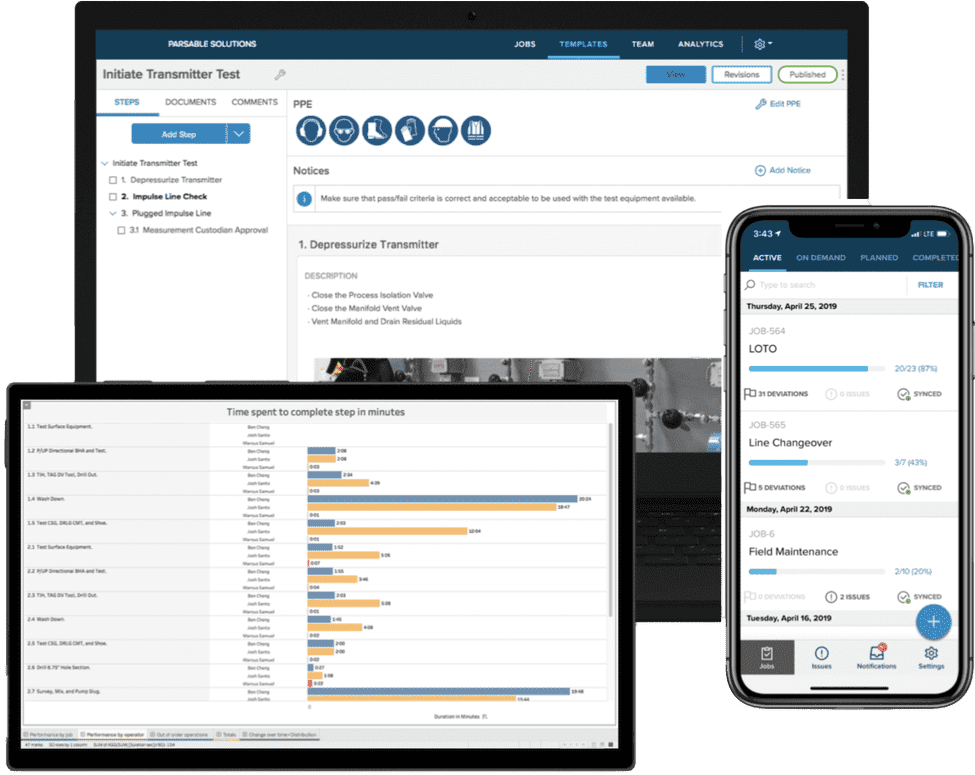

Parsable Connected Worker® digitizes manufacturers’ SOPs, reducing everything from time and material waste to injuries and accidents. SOPs can be updated in real-time to accommodate quickly changing conditions on the plant floor, ensuring sustainability best practices are quickly adopted across teams and work sites.