Conagra Brands Improves Quality & Reduces Downtime With Connected Work

THE CHALLENGE

Paper-based work instructions hinder collaboration and do not capture the complexities of various standard operating procedures. Conagra Brands wanted to improve operations at its plants by using a digital, mobile-first approach for its frontline employees to execute work, seek real-time help, access information quickly and collect actionable and accurate data.

The ACCENTURE + PARSABLE SOLUTION

As part of the Connected Shop Floor initiative, Parsable is the Connected Worker for Operations solution at Conagra Brands’ brand-new, $300-million production facility in Waseca, Minn., with four more sites planned.

Minimal IT Support

- Low-code/no-code platform

- Enterprise interoperability (SAP, etc.)

Quick to Implement

- Clearly defined use cases

- Professional services

Fast to Deploy

- Digitized templates in hours

- Familiar end user experience

Parsable is being used to perform CIL and centerline processes in many areas of the factory, including:

Quality

Enzyme testing

Air cleaning

Size grader

Production

Machine inspections

Clean in place

Vision system

Receiving

Truck/hopper inspections

Conveyor inspections

Sorter/scalper inspections

Shipping

Tote filling

Tote sealing

Tote X-ray

“Before, you would have to leave the floor, go to the shop, log in, etc. With this, if you have it on you, by the time it would have taken you to walk there, you’d already have it done.”

– Corbin P., Maintenance Lead

VALUE DELIVERED

Reduction in downtime

through timely, complete checks/audits performed by digitally connected employees

Empowered associates

who now have the digital tools and skills needed to autonomously run their processes

Reduction in errors

with automated quality triggers, reduced manual inspection, and rapid issue traceability

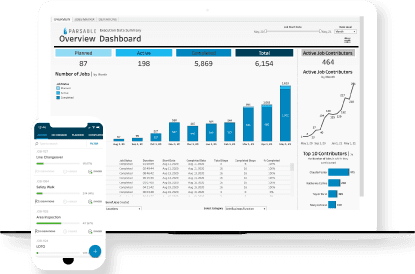

Improved data quality

resulting in more accurate data for better visualizations, reporting, analytics and insights