American Axle and Manufacturing Reaches New Heights With Insights From Parsable

American Axle and Manufacturing Reaches New Heights With Insights From Parsable

Company Background

American Axle and Manufacturing (AAM) is the world’s largest supplier of automotive driveline assemblies, commonly known as axles. Based in Detroit, AAM commands a global presence with 85 facilities across 18 countries and more than 25,000 employees.

AAM traces its history to the nascent stage of the automotive industry and continues to be driven by a mission of “advancing global mobility through innovative technologies and sustainable solutions.”

The Challenge

Though AAM has seen sustained success over many decades to the tune of $6 billion in annual revenue, all was not perfect. AAM requires all operators and supervisors to complete a quarterly audit process, reviewing job instructions to ensure everyone remains current and maintains high product quality and accuracy. Excel spreadsheets were being used to complete this task, but with tens of thousands of employees spread around the globe, it made it nearly impossible to track and ensure that all audits were fully completed on time. And because digesting and analyzing the results took significant effort, sites were required to submit proof of completion almost two months before it was due. Not only did it add stress to the day-to-day experience of associates and supervisors, it required these critical resources to focus their limited time on non-value added activities and put their pay, their bonus for completing these activities, at risk.

AAM products support electric, hybrid, and internal combustion vehicles; quite simply, they play a major part in the success of individuals and businesses in almost every industry. So, it is imperative that the products are made well and that quality standards are met. AAM also needed to have as much access to data and insights as possible, and for people to access those insights through a single source of truth, not a scattered web of solutions.

The Solution

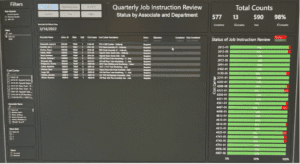

With that in mind, AAM went to work on implementing Parsable’s industry-leading Connected Worker®. Parsable technology filled the gaps left by Excel to enable seamless tracking of quarterly job instruction reviews across 85 facilities in more than 10 languages. In real-time, AAM can now track the status of every audit with bar charts and see where progress is lacking.

The platform is able to track activity data to provide visibility into the processes of frontline workers in every plant; newfound insights have enabled AAM to reach and exceed job instruction audit goals an entire quarter early.

“We use Parsable to collect and quickly access new data on frontline operations. This has helped us to reach new levels of data visualization and compliance to standard processes,” said John Klein, business systems leader, American Axle & Manufacturing.