Meaning of First Time Right (FTR) and How to Improve it

In manufacturing, getting things done right the first time is essential to optimize efficiency, eliminate waste, and save costs. However, production processes are complex, and it’s challenging to pinpoint where inefficiencies reside.

A structured approach helps manufacturing companies measure their ability to produce products correctly the first time. This concept is an actual metric called First Time Right (FTR). Below, we’ll explain what it is, how to measure it, and steps you can take to improve it over time.

- What Does the First Time Right Metric Mean

- How to Measure/Calculate First Time Right

- What Are the Benefits of a High First Time Right Metric?

- How Connected Worker Software Improves First Time Right

What Does the First Time Right Metric Mean

The First Time Right measurement assesses the percentage of correctly executed manufacturing steps on the shop floor on the first attempt. It’s a vital part of Six Sigma, aimed at continually making workflows better. Companies often use it to track redoing work and flawed products.

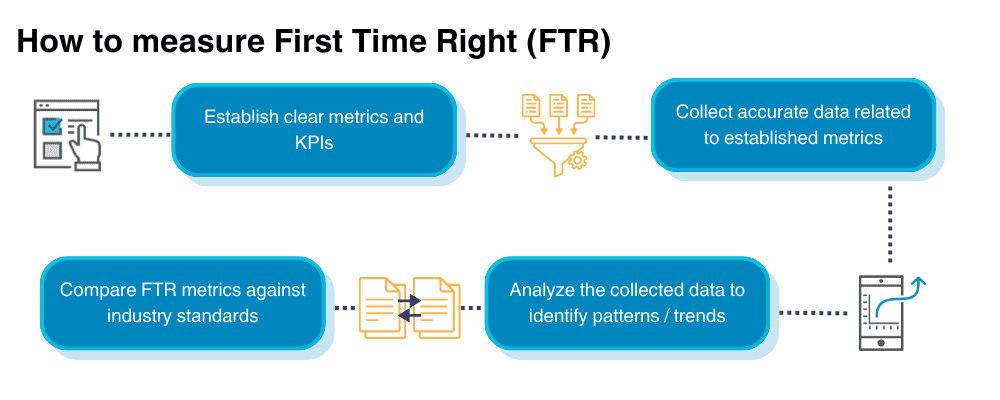

How to Measure/Calculate First Time Right

To calculate FTR, use the following formula:

First Time Right = (# of flawless products / # of total products) x 100

You’ll need to calculate FTR at every stage of product creation. To do this, add all of the FTR scores and divide them by the total number of scores. The goal is to get FTR as close to 100% as possible.

Now, achieving 100% is virtually unobtainable. The concept of Six Sigma itself even allows for a slight level of inefficiency. Yet, keeping an eye on the FTR percentage can help your organization in making data-based changes that will enhance your FTR.

What Are the Benefits of a High First Time Right Metric?

Understanding FTR helps companies gauge which production stages are most ineffective. From there, production managers can prioritize solutions based on projected operational inefficiencies.

Recognizing these inefficiencies enables the improvement of FTR. At this point, the actual benefits reveal themselves.

The benefits of high FTR include:

- Better profit margins

- Reduced waste and product defects

- Fewer stockouts and shortages

- Better quality products

- Increased customer satisfaction.

5 Steps to Improve First Time Right Metrics

Continuous improvement requires a dedicated process. It can be quite difficult to know where to begin.

Following these five steps, you can build a foundation for obtaining better FTR metrics.

Step #1: Define Issues

As mentioned, you calculate FTR at multiple production stages.

Once you’ve figured out FTR for each step in your production line, pinpoint the parts of the process that cause the most problems, like product defects. Then, rank FTR from lowest to highest across different stages.

Step #2: Calculate the Extent of the Problem

To get a clearer picture, calculate extra data points like how many products and materials are wasted, and the time spent redoing work. This provides a deeper insight into where your main issues reside.

Step #3: Identify Root Causes

Finding the root cause is the only way to eliminate inefficiencies. For example, if you discover that a section of your process is performing excessive rework, the rework is a symptom, not a cause. To fix the inefficiency, identifying the cause—be it human error or a defective machine—is crucial to make the right adjustments.

Step #4: Enhance Efficiency Through Process Changes

Improving FTR requires significant research legwork followed by clear, strategic changes to the production process. For example, if you have an issue with human error, don’t scold the employees and hope the problems will go away. Instead, find ways to incorporate training to boost skill and productivity or change the process to make it easier for employees to do their jobs.

Step #5: Monitor Performance After the Fact

Enhancing product development doesn’t end after making operational changes. You need to monitor and track all changes. For example, record the number of defective products after changing the production process. Then, see how much it improves over your previous number.

This way, you understand which solutions work and can continue applying successful strategies to increase FTR.

How Connected Worker Software Improves First Time Right

Enhancing FTR takes dedication, labor, and creativity. However, it becomes easier once you start incorporating it into your processes, especially if you also incorporate the right tools.

Research and invest in solutions to optimize efficiency and accuracy as you calculate, track, and monitor your FTR efforts. This way, you’re positioned to actuate change quickly and effectively.

These solutions should be data-oriented and capable of tracking progress in real-time. Then, you can reap the benefits, see profits rise, and continue satisfying customers to the best of your ability.

Still searching for the right solution? Try Parsable!

Our Connected Worker® app is a comprehensive suite for gathering operational data to glean insights critical to improving FTR.

Ready to revolutionize your operational workflows? Experience the power of Parsable’s Connected Worker® software firsthand. Schedule a demo today and discover how our solution can streamline your operations by digitizing your frontline.