Frontline Manufacturing Workers: Insights and Research 2021

We’re excited to announce the results of our international survey of 1,400 frontline manufacturing workers, now available in a new report, “The State of the Connected Frontline Manufacturing Worker, 2021.”

We all know the current global workforce shortage and skills gap crisis are challenging our industry in profound ways. The “Great Resignation” is adding to the already enormous labor challenges within the industry. The United States is predicted to leave as many as 2.1 million manufacturing jobs unfilled through 2030. Germany, Europe’s largest economy, projects that its workforce will shrink by about 4 million by 2030 as the baby boomer generation retires.

We’ve heard at length from executives and management about the business impact and how they’re trying to solve it. But what do frontline workers think? Do they feel that their companies are looking out for them? How does technology impact their workplace experience?

Our mission at Parsable is to empower workers with modern digital tools to improve productivity, quality, safety and sustainability. And since the start of the COVID-19 pandemic, it has become abundantly clear that people are at the heart of keeping companies and economies productive and sustainable.

So, we surveyed 1,400 frontline manufacturing workers across five countries (U.S., Germany, France, Spain and the U.K.) to find out how they perceive their jobs, their future, and the role of technology and digital tools in an increasingly complex environment.

The resulting primary data – in some ways, a collective voice from frontline manufacturing workers themselves – explores workers’ views on their jobs, the usage of workplace technology and the pandemic’s continuing impact. The report also provides three actions for manufacturing companies to consider in order to connect and empower their frontline teams, as well as an appendix that further analyzes data specifically on U.S.-based workers.

Here’s a summary of what we found:

- The opportunity to work in a more modern, digital environment would be part of frontline manufacturing workers’ decision to leave their current employer.

- More needs to be done, particularly on investing in digital tools, to stem the global labor shortage crisis and retain workers.

- Frontline manufacturing workers feel a greater sense of pride in their jobs and catching COVID-19 is no longer a top safety concern.

- Although today’s manufacturing facilities are far more technologically advanced, companies continue to use analog processes on the factory floor, limiting visibility and traceability.

Digital tools provide a way out of the labor shortage and skills gap

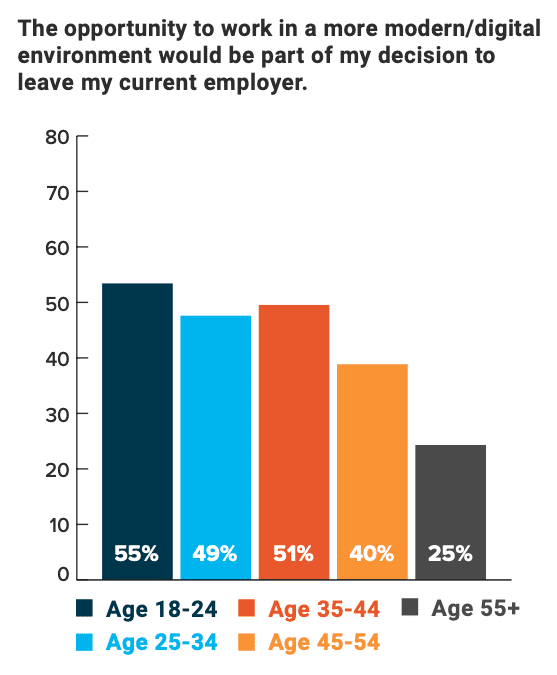

Convincing younger generations that manufacturing is a future-focused, technologically advanced career choice will become increasingly critical, and providing mobile-based digital tools and on-the-job learning opportunities are now tablestakes to ensure employees stick around. Our research found younger workers are more likely to leave their current employers for one that offers a more modern, digital workplace, including mobile technology: Across countries, 55% of respondents aged 18-24 and nearly half (49%) of those aged 25-34 say access to technology factors into such a decision, versus 25% of those aged 55 and older.

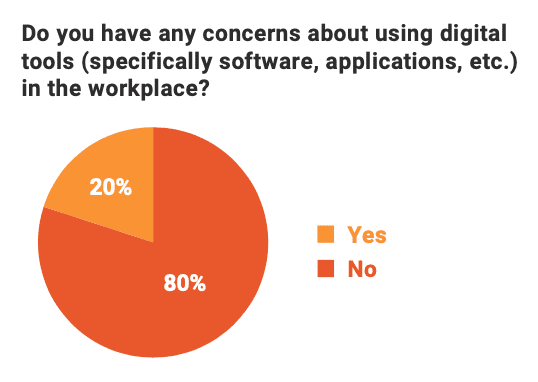

At the same time, older workers may be unfairly stereotyped as being technologically averse. Our research suggests that the vast majority (81%) of those aged 55 and older actually have no issues using software and digital tools at work.

Analog processes remain, meaning limited visibility and traceability

Although today’s factories are far more technologically advanced, the way frontline employees follow work procedures and collaborate with each other has largely been unchanged.

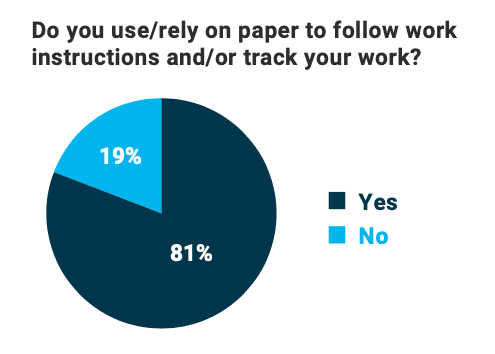

The majority (81%) of frontline manufacturing workers across all countries report using paper to perform and track their day-to-day job execution, even though 80% have no problems using software and other digital tools. When it comes to communicating with other team members, the top methods that workers rely on are verbally in-person (76%) and by phone (43%) – neither of which provide the visibility and traceability that digital channels offer.

Pandemic changed frontline worker outlook and highlighted tech benefits

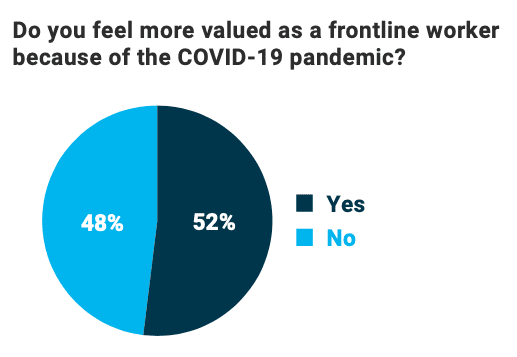

For those working in essential frontline manufacturing roles throughout the pandemic, the public spotlight has helped boost a sense of pride in their work. Across countries, 52% of frontline manufacturing workers say they feel more valued as a result of the pandemic. (For U.S.-based workers, that number is higher, at 63%.) Further, less than one in four (22%) of overall respondents reported that their primary safety concern at work is getting COVID-19, suggesting more confidence in personal health and safety measures.

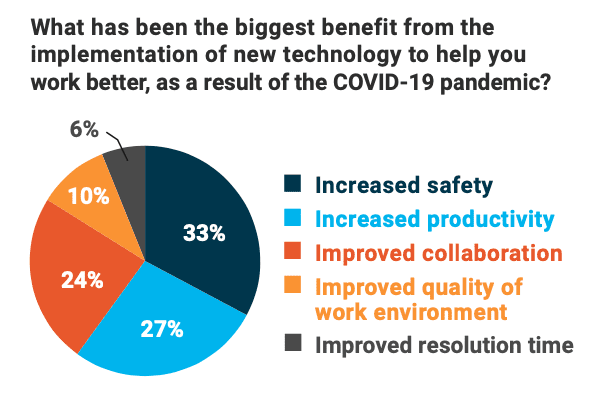

When asked if their companies rolled out new technology to help them work better because of the pandemic, 42% said yes. For those whose companies have provided new digital tools, workers believe the biggest benefit is increased safety (33%).

Our report outlines three key steps to get frontline operations off paper and into a more efficient way of working, by connecting frontline workers to people, information, systems and machines to improve productivity, efficiency, safety and sustainability.

To go in-depth with the research results and our recommendations, download the full report and read the press release.