What are One Point Lessons (OPLs) in Manufacturing?

Consistency is a core principle of building sound manufacturing processes. Consistency is critical for continuous improvement. It helps reduce human error and waste, which is essential for maintaining healthy profits.

However, manufacturing processes struggle to implement quick, practical training, given processes are often complex.

To remedy this, many operations issue one point lessons. Below, we’ll explain these lessons and how they’re necessary to share essential knowledge with all team members.

- What is a One Point Lesson?

- What Are the Objectives of a One Point Lesson?

- Use Cases for One Point Lessons

- Examples of a One Point Lesson

- How to Make a One Point Lesson

- How Connected Worker Software Enhances OPLs

- The Benefits of Digitalized OPLs

What is a One Point Lesson?

One-point lessons (OPLs) are single-page documents that outline specific tasks, starting with an action (V-ing) and concluding. Lessons can include maintenance, safety procedures, or quality standards. These lessons use straightforward text and visuals to explain processes, regardless of the topic.

Remember, people often mistake OPLs for standard operating procedures (SOPs). They are similar, but OPLs are more specific, using visuals, whereas SOPs cover multiple tasks and have more text.

All OPLs follow a few core principles:

- Conciseness: OPLs include only the essential elements needed for completing tasks without errors, starting and finishing

- Image-Reliant: Make OPLs mostly visual (90%) with simple, brief visuals to effectively convey the message

- Single Task-Focused: OPLs only cover one task at a time

What Are the Objectives of a One Point Lesson?

In factories and warehouses, OPLs cover a wide range of objectives while always maintaining succinctness

Basic Knowledge

OPLs are simple and effective, giving workers important instructions for important tasks, like cleaning equipment to avoid damage.

Error Prevention

Keep OPLs up-to-date to address safety procedures and concerns, ensuring the safest work environments..

Continuous Improvement

OPLs help express the results of continuous improvement initiatives, serving as guides on instilling Kaizen practices to increase efficiency.

Standardization

Success relies on meeting and maintaining health and safety standards, as OPLs provide employees with clear ways to meet these needs.

Communication and Collaboration

Communication failures waste time and materials, but OPLs outline proper communication channels to improve collaboration and eliminate waste.

Use Cases for One Point Lessons

Manufacturing managers use OPLs across all key areas to achieve autonomous maintenance, lean manufacturing, and just-in-time production. Below are some common OPL use cases.

Troubleshooting

Manufacturing processes involve lots of complicated, error-prone equipment. Managers should create OPLs to address all potential error codes. Then, when a code appears, employees can reference specific documents without delay.

Quality

Maintaining peak production quality requires paying attention to many small details. OPLs build consistent quality assurance practices, such as a guide about product handling or packaging materials correctly. These documents lead to more consistent quality and reduce the likelihood of flaws.

Procedures

OPLs are excellent for spelling out specific tasks and procedures with inflexible rules like equipment operation and maintenance.

Safety

OPLs help enhance safety in everything from equipment operation to on-site uniform requirements.

Communication and Collaboration

Use OPLs to visually promote collaboration by outlining communication hierarchies and establishing a command point at each workstation.

Examples of a One Point Lesson

As stated, OPLs work best with clear visuals with simple text. Below is an example of how to build an OPL to clean a factory machine.

The OPL would display an image of the machine and highlight each part requiring cleaning. From there, build a checklist with simple instructions, ensuring the employee knows exactly when they’ve accomplished the task. Don’t forget the room for key details, like the date, time of cleaning, and employee name.

How to Make a One Point Lesson

A handful of ways to create an OPL include:

- Printed Copies from Excel, Word, or PowerPoint

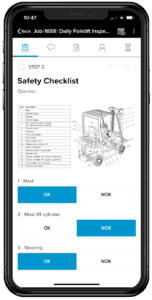

- Digital-only creation tools, such as a connected work software platform

How Connected Worker Software Enhances OPLs

To maintain efficiency and accessibility, prioritize creating OPLs using connected worker software as the ideal approach.

With the right connected worker software, managers can create, approve, and store OPLs in a central location. From there, employees have a digital OPL hub, eliminating the need to lug around a bulky binder.

The Benefits of Digitalized OPLs

Digitizing OPLs comes with a wide range of benefits.

Enhanced safety is the first and most crucial benefit, as OPLs offer immediate access to training and information. If an issue arises, management can promptly instruct employees, ensuring safety and preventing recurring mistakes.

However, digitized OPLs also enhance efficiency with database centralization. Quick access helps employees stay focused, leading to increased productivity and greater success in continuous improvement efforts.

Consider Parsable’s Connected Worker® platform if you’re interested in investing in a comprehensive suite of digital manufacturing management tools. Our platform includes a fantastic tool for creating, storing, sharing, and updating OPLs.

Ready to revolutionize your operational workflows? Experience the power of Parsable’s Connected Worker® software firsthand and discover how our solution can streamline your operations by digitizing your frontline.