3 Key ESG Trends: Sustainable Industrial Manufacturing Event

A not-so-fun ESG fact: Heavy industry (cement, steel, aluminum, glass and chemicals manufacturing) is responsible for 30% of carbon emissions. A cleaner approach to manufacturing and production would have an incredible global impact on addressing sustainability, climate and environment targets.

Learning how to reduce the environmental impact of industrial manufacturing was the goal at the recent “Sustainable Industrial Manufacturing Series (SIMS) Conference” in Brussels, Belgium, which attracted over 2,000 attendees from around the world.

Learning how to reduce the environmental impact of industrial manufacturing was the goal at the recent “Sustainable Industrial Manufacturing Series (SIMS) Conference” in Brussels, Belgium, which attracted over 2,000 attendees from around the world.

SIMS hosts industry, innovation, science, government and investment leaders to support and facilitate the transition toward cleaner and sustainable manufacturing worldwide and across those five hard-to-abate heavy industry sectors.

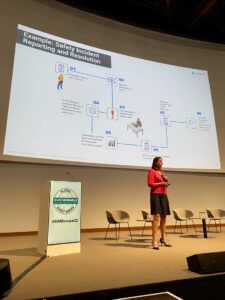

The Parsable team was on hand to explain how connected worker technology could make data-driven sustainability improvements across manufacturing operations. Yasmin Zarabi, Parsable’s Head of ESG and General Counsel, presented a keynote on the main stage.

The overarching theme from SIMS was that achieving this level of impact requires a collective, multi-stakeholder approach. It’s the only way to address the issue at the pace, scale and depth required to achieve sustainable manufacturing goals.

The key trends that emerged from the multiple learning streams of “Energy,” “Evolve” and “The Environment” was that success and progress require a combination of regulations, sustainable product innovation and technology.

ESG Trend #1: Increasing ESG Regulations and Buying Pressures

For companies to be more serious about taking action requires coordinated endorsement. Recognizing this, European regulations designed to protect the environment and drive sustainability are on the rise – and are focused both on industry and individual corporations. In fact, on the day of the SIMS conference, the environment ministers from the 27 countries in the European Union reached a deal supporting the phasing out of fossil-fuel cars by 2035 and a €59 billion fund to help ease the cost burden of these new policies on low-income earners by shielding poorer citizens from carbon dioxide (CO2) cost.

There’s also an aligned financial incentive for businesses to meet these requirements. When B2B and B2C consumers are increasingly vocal about and motivated by their power to choose with whom to do business or buy goods, no company wants to be in the news about environmental wrongdoing.

ESG Trend #2: Sustainable Product Innovation in Manufacturing

Sustainable product innovation was at the forefront of the five sectors. The core and common ambition for all is to reduce waste in landfill disposal by replacing critical raw carbon-based materials with bioresources.

Conglomerates in each sector continually innovate and iterate to create end products that reduce emissions, waste less and are better for the environment.

These industries are looking at new raw materials and laboratory equipment, contemporary design methods, and premium technologies to help them implement, scale and operationalize these targets.

ESG Trend #3: Role of Technology and Frontline Manufacturing Workers

However, sustainable product innovation and regulations are not complete or feasible without the rapid deployment of new technologies to ensure all aspects of production, the supply chain, and regulatory reporting keep up with compliance and do so efficiently and cost-effectively.

All of which require technology.

As mentioned, Yasmin Zarabi, Parsable’s Head of ESG and General Counsel, gave a mainstage keynote that addressed how technology can close the gap between compliance with regulations, sustainable manufacturing, and accurate reporting. Technology also closes the gap and empowers the most valuable manufacturing asset – the frontline worker.

Technology like connected worker platforms can provide business leaders real-time visibility into their frontline teams. And teams can use this data to optimize their productivity and ESG efforts further. It also provides frontline workers with real-time support and increased connection to one another, improving team engagement and output. That’s how Parsable fits into the operationalizing of global manufacturing sustainability.

Parsable assists frontline workers in operating with best practices every time across all aspects of ESG and sustainability, unlocking critical data to enable organizations to improve as they progress toward their environmental impact goals.

Parsable is a technology solution, but it interacts with our most important means of change on Earth: people.

Ultimately SIMS was a call to action to unlock the power of the frontline workforce and operationalize the industry’s sustainability goals. Central to this call is providing the digital tools needed to work more efficiently and effectively, as well as capturing the data and generating the insights for companies to monitor and measure progress across waste, CO2 emissions, and energy and water usage.

Parsable is proud to have been part of SIMS and to share how our tools and platform are part of the digital solution needed to drive this urgent industry transition.