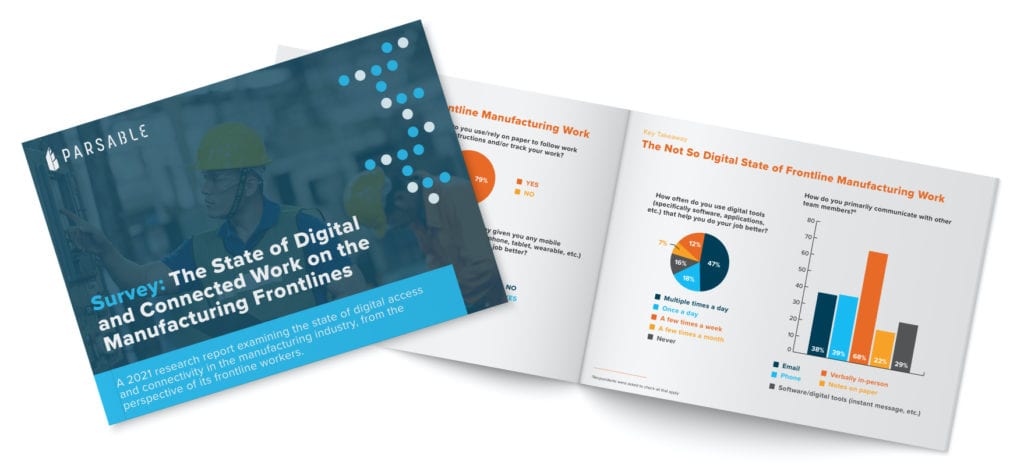

New Research: The State of Digital Transformation and Connected Work on the Manufacturing Frontlines

We’re thrilled to share the results of our survey of 1,168 U.S. manufacturing workers, now available in this new report, “The State of Digital and Connected Work on the Manufacturing Frontlines.”

This inaugural research explores the technologies that frontline manufacturing workers are being given to help them do their jobs, their usage of digital tools in the workplace, and how age and generational differences come into play. The report also provides six actionable next steps for you to quickly improve your frontline operations with technology.

Since Parsable was founded in 2013, our mission has always been to empower workers with modern digital tools to improve their productivity, work quality and safety. For far too long, deskless workers – which make up 80% of the global workforce – have received a miniscule amount of investment in software solutions that help them with their jobs. This needs to change.

Manufacturing has reached a tipping point. Going “digital” and modernizing operations is now table stakes and seen as non-negotiable in manufacturing and industrial operations. But the question remains, are frontline workers getting access to digital technology?

Here’s what we found:

- Frontline workers want access to digital technology to empower them to be successful in their jobs

- Management is missing opportunities to digitally empower frontline workers

- Companies that don’t close the digital gap will lose frontline talent

Good Manufacturing Practices = Access to Digital Technology

A staggering 79% of factory workers still rely on paper-based documentation and checklists to track work and communicate with their team. In many cases, management has been hesitant to move away from paper-based standardized operating procedures (SOPs), workflows or checklists to digital work instructions. The reason for this might be because they’re concerned that technology in general will create more work for employees or be difficult for them to use. However, our research suggests that frontline factory workers are now ready more than ever to embrace new technology in their day-to-day operations.

Frontline workers want access to technology and nearly three-quarters of today’s frontline workers (72%) expressed no concerns about using digital tools in the workplace (including 69% of Baby Boomers).

Missed Opportunities for Digital SOPs and Going Digital

While manufacturing workers are ready for digital tools to be introduced into the workplace, some management teams still haven’t taken the steps to digitally empower their team. At the moment, only 47% of frontline workers said they have access to mobile technology through their workplace – be it a smartphone, tablet or wearable device to help them do their jobs efficiently.

It’s evident that there’s a lack of digital tools within manufacturing operations, and outdated paper-based checklists and ways of working are hampering productivity, efficiency and safety.

So, if workers aren’t given access to technology, then how are they completing their tasks? A majority are still being asked to use paper-based documentation.

A Digital Gap Means Lost Talent

The current digital gap in the manufacturing industry will likely negatively impact a company’s ability to attract and retain talent. More than half (52%) of factory workers surveyed would consider leaving their current job if offered the opportunity to work in a more modern, digital environment.

Furthermore, our research confirms that Millennials and Gen Z are more likely to have short tenures: 56% have been in their current manufacturing role for less than two years, and 27% intend to move on to a different company within two years.

It’s very much apparent that if companies do not act fast and take these matters seriously, they will run the risk of high employee turnover.

So what should you do with this new data and knowledge? Our report outlines six key steps to get your frontline operations off paper and into a more efficient way of working that reflects the modern, technology-forward world we all live in.

For more new data and to go in-depth with the results and our recommendations, download the full report and read our press release.