How to Achieve Sustainable Manufacturing With Modern Digital Technology?

A version of this article was originally published in Manufacturing Leadership Journal.

For all the turmoil that the COVID-19 pandemic has brought to the world over the last year, it has also provided a unique catalyst for the world’s manufacturing community to reimagine business and operational models and advance towards a more viable and sustainable future.

The World Economic Forum’s latest framework around environmental, social, and governance issues (ESG), which was launched in the wake of COVID-19, is now challenging global leaders, including manufacturers, to commit their organizations to be even more resilient and sustainable in the years ahead.

And there are many urgent reasons for this that specifically apply to the industrial world.

Manufacturing’s Sustainability Imperative

From an environmental impact perspective, industrial production statistics are mind blowing. Globally, 25% of heat-trapping greenhouse gas emissions, the largest single source, come from the burning of coal, natural gas, and oil, of which a significant amount is due to industrial activity. Manufacturing currently consumes around 54% of the world’s energy, according to the U.S. Energy Information Administration (EIA) and is the source of 22% of greenhouse gas emissions in the U.S.

Encouragingly, the use of cleaner, renewable energy sources is increasing all the time among industrial corporations as more and more companies announce, and strive to meet, their Net Zero CO2 targets for production and supply operations in the next few decades.

The UN’s Race to Zero campaign, for example, noted that the number of commitments to reach net zero emissions from businesses and local governments in 2020 doubled in less than a year as organizations prioritized climate action as part of their recovery strategies from COVID-19. This trend is likely to continue to accelerate in the year ahead as national industrial policies, including from the new Biden administration in the U.S., put a renewed focus on climate change issues and emissions reduction.

The growing number of industrial sustainability commitments is not just helping to improve the planet either. It is also helping to improve individual company talent pipelines too. For example, according to a recent survey from clean energy platform Swytch

70% of millennials say a company’s sustainability record directly impacts their decision to work for and stay with an organization.

Manufacturers already face a fast-approaching crisis with employee recruitment and retention. Baby Boomers are retiring in droves and taking their tacit knowledge with them, while millennials, unimpressed with the perception of manufacturing as a potential career, hesitate to enter the industry. This leaves a potential gap of 2.4 million unfilled manufacturing jobs in the U.S. alone by 2025. Creating more attractive and sustainable industrial environments for the next generation of workers is now critical to the industry’s ability to engage and retain future employees.

2020 may have been the year of COVID-19, but it also delivered palpable evidence that the industrial world is increasingly realizing that sustainability must, and will, lead strategic business decisions in the next decade and beyond.

It’s perhaps no surprise then, that in the Manufacturing Leadership Council’s December 2019 survey

80% of respondents now consider sustainability as either essential or increasingly important to their company’s future competitiveness and growth.

What key developments should we expect to see in manufacturing as the industry strives to embrace a more sustainable future.

A Digital Transformation Foundation is Key

Before any meaningful sustainability effort can take hold, the foundation for digital transformation must be built and leveraged by everyone. Without technology to support and scale them, sustainability strategies will, in all likelihood, never move forward effectively and swiftly.

In its white paper, Shaping the Future of Production: Four Contrasting Perspectives in 2030, the World Economic Forum posits a future-state scenario where “virtual ecosystems, propelled by human-machine collaboration, marked by real-time communication and integration on the floor, linked with external environments simultaneously … have replaced the non-automated, wasteful and inefficient models of the past.”

Today, many manufacturers are still in the earlier stages of that transformation. Even for those that stand out as innovators, scalability remains an issue. Yet providing each and every frontline worker with modern digital tools is one of the easiest ways to drive awareness of how to positively impact sustainability. By systematically using digital tools through every industrial standard operating procedure, companies can unlock rich new data sets to increase productivity, quality, and safety, which intrinsically improve overall sustainability. Providing reliable wireless connections on the factory floor, personal mobile devices and wearables, and access to advanced analytical tools for all workers should be a basic requirement for all manufacturing businesses to help drive that awareness and optimize processes at the plant level to reduce rework, material waste, energy consumption, water usage, and non-reusable components.

Establish End-To-End Supply Chain Sustainability

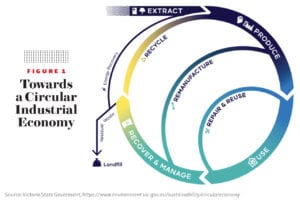

Within the next decade, manufacturers will increasingly put sustainability at the core of their strategies and design their operations and business models around a sustainable value delivery mechanism. The end-to-end supply chain from raw material to finished product provides major opportunities to drive sustainability. Traditional manufacturing processes that follow a linear “take-make-dispose” product lifecycle will be replaced with circular production economy approaches that embrace a transparent lifecycle of reuse, remanufacture, and recycle. According to the UN Environment Program, remanufacturing, refurbishment, reconditioning, and improved maintenance of products can result in a reduction of as much as 98% in CO2 emissions.

Advanced technologies are now widespread enough to support this, from AI/ML, to digital twins and IIoT devices, to connected worker platforms. In tandem, the combination of supportive policy changes, incentives, and shifting consumer preferences will propel the circular production economy into manufacturing’s mainstream.

The good news is that this shift is already moving in that direction. According to the 2019 Manufacturing Leadership Council survey, two thirds of manufacturers said they have formal design criteria built into their product development processes that consider ways to lessen the environmental impact of a product and its end of life, including recycling materials, reusing components, remanufacturing, refurbishment, or easier disassembly. By 2030, that number is likely to be much closer to 100%.

Localized Production

By 2030, we’ll also see new configurations of manufacturing and supply systems that focus on localized operations involving micro-factories, shared factories, or “next-door” factories. A manufacturer that used to have 15 plants serving a large region will switch to 150 smaller ones, many of which will be located close to where its customers live. Warehousing and transportation, which are resource-heavy and generate significant amounts of waste and CO2 emissions, will also be greatly reduced in the process.

Local supplier options, too, have increased. In the U.S., the offshoring trend has now begun to reverse, reducing the global environmental impact of manufacturing in developing geographical regions. One study calculates that 17% to 36% of four major air pollutants emitted in China come from the production of products and components for export markets.

Local small and medium-sized suppliers will also see a resurgence with the help of increasingly affordable cloud-based automation platforms and cost savings from digitally connecting their workforces. As a result, manufacturers will be better able to handle demand volatility and any issues that might arise along their supply chains in a more sustainable and environmentally friendly way.

With all that’s happened in 2020, it may be difficult to imagine what work and life could look like in a few years’ time. However, we have a lot to look forward to as an industry, especially in the area of sustainability and climate positivity. The move towards more sustainable factories and the circular production economy is already underway. As one of the biggest drivers of the global economy, it’s now manufacturing’s responsibility, and its opportunity, to help ensure the world is healthier and more vibrant for everyone in the years ahead.

©2021 Manufacturing Leadership Council, a division of the National Association of Manufacturers. All Rights Reserved.