For Coca-Cola European Partners Deutschland, It’s Easier Digitally With Parsable

This is a translated version of an article that was originally published in PROCESS magazine Germany.

Coca-Cola European Partners Germany (CCEP DE) has taken the networking of its employees in production and logistics to a new level – and is achieving far more than just leaner processes.

The market for beverages in Germany is complex. Depending on their lifestyle and the context, customers consume soft drinks in cans, PET or glass bottles in a wide variety of sizes. In addition, Coca-Cola European Partners Germany (CCEP DE) has approximately 325,000 retail and foodservice customers in Germany that expect customized concepts that keep pace with new market and service trends – all while bottling and selling 3.5 billion liters of mineral water and soft drinks in Germany every year.

This poses challenges for CCEP DE’s approximately 7,000 employees. The complexity of the supply chain is growing and the demands on the workforce in production and logistics are increasing.

“We may have to change over three or more times a day, plus cleaning shifts. And the more often we change over, the more points we have to consider daily in order to maintain our high standards of product quality,” explains Steffen Löser, who as CCEP DE’s Manager Processes & Solutions is responsible for supply chain processes, further development and standardization in Germany.

Digital assistance as an important strategy for the future

As part of its “Fit for Future” strategy, CCEP DE is continuously looking for digital solutions, with the intention to both relieve employees and at the same time strengthen the company’s competitiveness. One of the pillars of this strategy since 2018: digital assistants. What back then was common in the sales organization – the networking of employees with mobile devices – needed to find its way onto the store floor. There were already demands from the workforce.

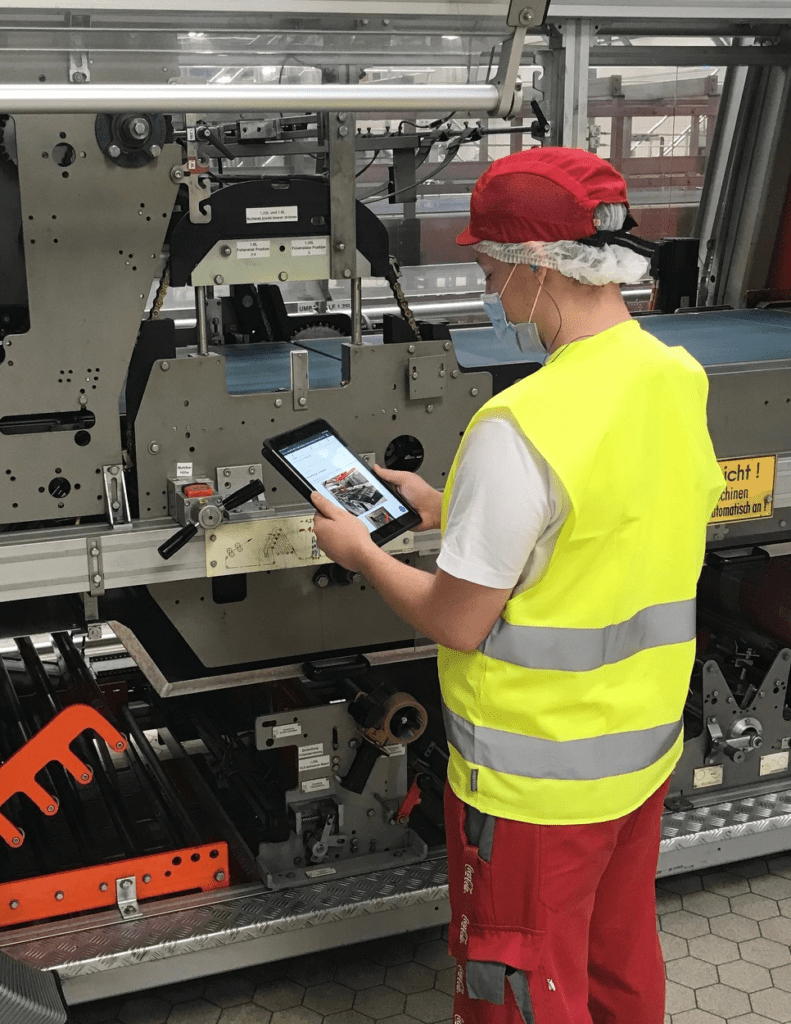

After a comprehensive search for suitable solutions in 2019, CCEP DE launched its initial test with Connected Worker® by Parsable. The aim was to support employees directly at their workplace with electronic instructions and interactive checklists. Using a smartphone or tablet, they would be able to comply with all specifications and standards and protect against errors. This would also put an end to the manual transfer of information from paper notes to electronic documents. “Even if we are only eliminating the necessary effort of a few hours per week, this results in a relevant time saving over the year,” Löser emphasizes.

Saying goodbye to paper boosts the flow of information

The Parsable pilot sites in Genshagen, Knetzgau, Lüneburg and Mannheim initially addressed the cleaning, inspection, and lubrication (CIL) processes. Until then, instructions had been stored on paper in ring binders. Employees confirmed completed work on paper lists, which were later partially manually transferred to Excel for documentation and reporting. Together with experts from Parsable, these paper-based procedures were transformed into image- and video-based instructions.

“In the Parsable app, the instructions are now available to employees as needed. A worker sets the checkmarks, confirms that all is done, and automatically all the data is documented. The process has definitely become more streamlined and faster,” says Löser.

From fire protection to maintenance

After the first positive experiences, CCEP DE expanded the use of the interactive instructions to other production-related areas. Today, Parsable is used in maintenance as well as in quality management, warehousing, transportion, and distribution. Worker and shelf safety is checked just as much as fire protection.

One of the added Parsable use cases is Gemba Walks. During these walks, managers and employees verify the operation with regard to anomalies. If everything is running correctly, they check the box in the Parsable mobile app. If not, they record observations via photo and video within the app, inform the responsible colleagues directly, and immediately initiate the necessary measures.

In logistics, another Parsable use case is currently being rolled out in the form of checking the technical readiness of the company’s trucks. Before the drivers leave the yard, they must check whether the vehicle is technically faultless. If they find any defects, Parsable guides them through the defect handling process.

Ease of learning meets enablement

The positive cost-benefit results of using Parsable come not only from the streamlining of processes, but also from reduced familiarization and training requirements.

“We could prove that Parsable saves time, especially for new frontline workers,” Löser says. “To test this, for example, we gave one of our trainees the task of changing a machine over completely unaccompanied, with only digital instructions in Parsable. He did it flawlessly and even faster than usual.” It’s not just ‘digital natives’ who can get started quickly. The older employees find the Parsable app intuitive to use.

Implementing new use cases with Parsable is easy because CCEP DE administrators do not need any programming skills. As a result, says Löser, surprising talents have been discovered in the organization: Supported by Parsable, some employees have developed smart solutions with zeal and skill.

“We find that exciting. That means Parsable is also a bit of a catalyst for bringing out talent at the department or site level,” says Löser. In that respect, he sees the platform as an enablement tool as well. To promote creativity and exchange among the 30 or so administrators, CCEP DE has established an internal community. It helps with the transfer of best practices between the sites as well as with the development of new use cases – supported by Parsable’s expert team.

Controlled use of resources

Parallel to its digital transformation, CCEP DE is also pushing the issue of sustainability. The company’s goal is to be climate-neutral by 2040. Here, too, the digital helpers have a positive effect. Saving paper is the smallest lever. Other effects are far more significant: For example, the start-up and shut-down checklists for the production lines help to reduce consumption of water and electricity, and to save energy in the generation of compressed air. According to Löser, “Because we perform all checks reliably in Parsable, costs and sustainability-related issues are positively impacted.”

“Parsable enables complete documentation, as data for each task is stored and can be retrieved when needed,” says Löser. Of course, this would be done in close consultation with employee representatives and data protection officers, as the aim is never to monitor the performance or behavior of employees, but to ensure timely and correct execution while identifying starting points for process optimization.

Contribution to a functioning supply chain

Parsable Connected Worker® is currently in use at almost all 14 German bottling sites at CCEP DE. There are over 400 users using the app regularly, and the trend is rising with new use cases and organizational units added constantly – for example, adding the Cold Drink Operations unit, which is responsible for the technical maintenance of Coca-Cola refrigerators and sales equipment in the market.

Although the dynamics of COVID-19 have so far made it difficult to express the long-term benefits of Parsable in reliable figures, Löser has long considered the connected worker program a success. “We had high expectations, and to date, they have been met. We have also been very satisfied with the quality of service from the Parsable team.”

He concludes, “Parsable contributes above all to the fact that our supply chain continues to function smoothly despite increasing complexity. After all, we can see how much it simplifies employees’ day-to-day work and is correspondingly well adopted.”

Discover other leading industrial companies across the world that trust Connected Worker® by Parsable.