The Next Gen of Industrial Leaders w/ WEF & Parsable

Internally, retaining talent requires you to invest in reskilling and upskilling with a culture of continuous learning in short and convenient increments.

Externally, recruiting new talent requires you to partner with universities to train for the skills we need and make the industry even more attractive with digital transformation.

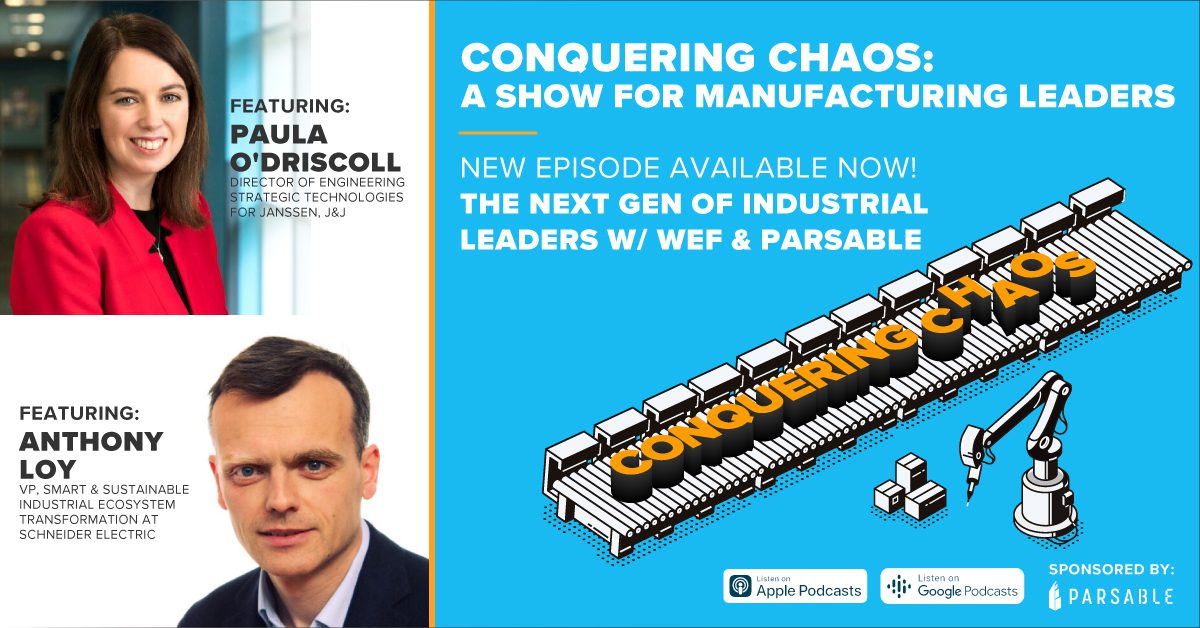

In this episode, we have a conversation about building the next generation of industry leaders with two fantastic guests:

Paula O’Driscoll, Director of Engineering Strategic Technologies for The Janssen Pharmaceutical Companies of Johnson & Johnson

Anthony Loy, VP, Smart and Sustainable Industrial Transformation in Schneider Electric

______________________________________________________________________________________________________________

Are you ready to start your digital transformation journey? Request a demo today.

______________________________________________________________________________________________________________

Check out the full episode below:

[00:00:00] Anthony: Every digital transformation leader has under his own responsibilities the creation of the learnings required to be successful. Me, my team, I had to create the learnings. At the same time, as we were delivering the solutions for the digital transformation.

[00:00:22] Josh: Welcome to Conquering Chaos, the show for manufacturing leaders. In each episode, we are connecting you to the manufacturing leaders of today who are driving the innovations needed to future-proof the operations of tomorrow. If you feel like your time is spent fighting fires and trying to control the everyday chaos, this show is the show for you. My name is Josh Santo. I’ll be your host.

Hey all, it’s Josh, before we get into this episode, I wanted to put this into your ear. If you like the types of conversations we’re having, you’ll enjoy the content that we share through our mailing list. Go to parsable.com/podcast, scroll to the bottom of the page, and sign up to get more insightful content delivered directly to your inbox. Onto the show. Welcome to the show. Today’s episode is a special one. The new generation industry leaders community, which is part of the World Economic Forum and Parsable are working together to bring you focused conversations on what you can do to bring the younger generations into your organization.

The new generation industry leaders also known as the NGIL engage across the world economic forums platform to shape and drive new ideas that transform the industry, including promoting industrial careers to younger generations, especially Millennials and Gen Z. Our guest today, she’s the director of Engineering Strategic Technologies for Janssen, J&J. She’s one of the key strategists behind the design and implementation of the digital systems at the Janssen Cork Ireland manufacturing site, which was designated as a global lighthouse site in 2020.

We also have the VP of Smart and Sustainable Industrial Transformation at Schneider Electric.

His accomplishments to highlight include leading Schneider Electric global supply chain smart factory transforming a hundred sites– actually more than a hundred sites in smart factories globally. Five of those were designated as lighthouses or are developing globally. Please, welcome to the show, Paula O’driscoll, and Anthony Lloyd. Paula, Anthony, thanks for being here today.

[00:02:43] Paula: Hey, Josh. Thanks for having us.

[00:02:44] Anthony: Thank you, Josh.

[00:02:44] Josh: We like to start out this show by getting a feel for what the day-to-day is like in these very unique roles that the people who come on the show have. I would love to hear just quickly from each of you, what does your day-to-day look like?

[00:02:58] Paula: Okay, I’m married with two children. I live and I’m working from home now in my beautiful West Cork in the south of Ireland. In my work, I’m responsible to develop and execute the digital and asset management strategies for the large molecule biologic sites, which are part of the global Janssen network.

[00:03:18] Anthony: Yes. On my side, the day-to-day, it’s interesting. I live in Singapore. When you have a global role here, you really have your mornings to reflect and learn a lot. When you speak about digital transformation in the industry, when you speak about sustainability, things are moving very fast. I would say, I have a large share of my day, which is about learning, but then you need to start building, building your network, building transformation. I would say, we are so busy afternoon and night working with the overall supply chain, working with our partners, some customers, and suppliers, directing that transformation, advising, and making sure that we are always going in the right directions when we speak about our transformation. A lot of learnings building and transformation.

[00:03:59] Josh: It’s great to have both of you. It’s great to be able to bring on guests who are representing such an innovative organization and particularly the fact that while both of your roles may be different in the title, in day-to-day responsibilities, there’s still this underlying theme related to innovation, driving things forward and that’s what we’re excited to discuss here today. One of the first topics that I like to bring up and that I would love to start the discussion with you is the future workforce. What comes up pretty consistently is the skills gap and the need to recruit and retain the next generation of workers, which include the Millennials, more and more Gen Z, and eventually Gen Alpha.

I think what we would all agree on and what’s clear is that something has to change. Current efforts aren’t effective and it’s not just about how you recruit, but also the type of working experience that you provide for the people that you employ. The way people spend a significant portion of their day really matters, especially to this younger generation. Like many things, one of the best first steps that you can take is to look at what you have now and where the gaps are. This is especially true for the skills that are needed to support popular initiatives related to digital transformation in Industry 4.0.

My question to both of you is, how do you evaluate the gap in skills to deliver the opportunities afforded by the fourth industrial revolution?

[00:05:41] Paula: Josh, it’s critical to understand the plan for Industry 4.0 deployments across the business, such as advanced analytics, smart assets, artificial intelligence, and what types of a technical process or customer deployments are planned. This then provides directional context and focus to identify what skills are needed, when they’re needed, and what’s the duration of the need, and then you can assess what people skills and capabilities are already available and where your gaps may exist.

[00:06:13] Anthony: If I may add on top of what Paula just said. I still have three areas where you should focus in terms of skills. There are obviously core digital skills and here we can speak about the capacity to develop software, design architectures, networks, solution design, and so on. On top of that, I would integrate a layer of design thinking. Meaning, the capacity to understand your user needs, the core needs, the pain points, the opportunities that you have with them, and the challenge you need to address and to design the right solution and the right approach. Now, there is probably also an innovation attitude that you need to cultivate, I would say.

That’s something that you don’t really need to recruit it externally. You need to give authorization internally to innovate and show the way and business to come from the leadership. Finally, the capacity to have really a transformative approach, really, adding incremental steps. Thinking about where do you want to go, but taking incremental steps that help you to do this transformation. What we saw within the 100 sites that we have is that those sites who had the right leadership, but especially these skills, this attitude, and this transformative approach, were really the one who was able to go much faster in that transformation with a qualitative output.

[00:07:36] Josh: There’s a couple of things that both of you called out that I think really stand out to me, Paula one of the first things you said is you have to understand what that future looks like or what that roadmap is for, how operations are going to change or how the business is going to change factoring in these different types of technologies and these different types of technologies depending on what they are, advanced analytics, artificial intelligence, two of the ones that you called out, those are going to drive a need for specific skill sets.

Understanding what that future roadmap looks like, then helps drive the understanding of, “Here’s where our gaps are. Here are the things that we need to do to fill it.” Then, Anthony, some of the things that you called out breaking it down, not just from a skill set but you also have to have the right leadership in place that sets the right culture in place. I think that that’s pretty critical that this is not necessarily just a skills gap. Skills gap is a piece of it, but you have to have the right vision in place and you have to have the right people in place to make it okay to explore these opportunities, to encourage the curiosity that comes with that drive, that attitude for innovation.

I think those are pretty key takeaways that it’s not just who do you need to bring in, but who do you need to enable internally to then bring in the right people. Now I’ve got another question, a follow-up question for both of you, how have you or how are you planning to address these skills gap?

[00:09:12] Anthony: What we had to do after, let’s say probably after 6 to 12 months in the journey and where we realized that skills we are already making the difference. We started with a very comprehensive self-assessment and then a proper survey of our different populations if I may say. Here, we really address managers, leaders, home client workers. Several thousands of people were assessed in different geographies, different functions, so that we could have the right mapping in terms of where we were probably under-skilled and here we can speak about that analytics.

We can speak about basic digital knowledge as well. Sometime, you need to come back onto basics. Also, what do you mean when you speak about digital transformation? It means a lot of things but but sometimes, a different meaning to everyone. We have this mapping, with this mapping, we took the detail on digital leaders that we had, we had some leaders on analytics for supply chain, on IoT, via robotics, and so on. We created specific learning paths with our learning academy. These learning paths were really tailored for your job position, what do we expect from you in your position.

If you are, for instance, a quality engineer, what are the right skills that you will need in the coming years in your domain? We created these learning paths which are still evolving, obviously, today. The second thing is that we have internally a program that we call Edison. Our Edison program is our internal recognitions of expertise. We have several levels of expertise and those were level three our global experts recognize even outside of the company by their peers. It’s a way for us really to promote competency in itself. There are some product competencies, there are some supply chain competencies, manufacturing.

We created a digital segment in Edison which is embedding analytics, IoT, manufacturing software and all industry for data applications and data management. Because we saw it was the right time for us to notify this population of high skilled, and we have probably around 40, 50 people today in this population who are globally recognized as experts. Now we are relying on these people to build the larger community. Finally, what we do every time we address competency is that we have a proper job description and competency management system.

For instance, a position description, I’ve got the list of competencies but we update these competencies, we update this level of requirement every time we do it for submission because that’s really a way for us to standardize globally and to really measure where we are everywhere on a yearly basis and then to support people to become let’s say, future-proof in terms of skills.

[00:12:10] Paula: For Johnson Johnson, I would say it depends. Closing the skills gap can be built by your borrower or sometimes called a contract decision, depending on the type of skill that’s needed, or the urgency or the duration. It may be a talent acquisition play, where it’s to hire into the organization. In many cases, current employees will have the opportunity to upskill which is enhancing their current skills and rescale which is building the new skill. Building skills right across the digital space is a major focus for us right now such as advanced process control and data analytics.

In some cases, we may need to hire or contract individuals who already have the specialist skills required, especially where the gap is very large, or duration of the need is short term. An example of that would be application development.

[00:13:03] Josh: With those, there’s a little overlap in those answers but I like that ultimately, Paula and Anthony, you’re both describing a couple of different ways of addressing this. I think what that highlights is that there’s no right or wrong approach. What is clear is that you have to evaluate what you can do and make the decision that works best for your business. Anthony, what I like about what you called out, you started with the baseline, where are we today? Let’s pull the workers that we rely on to understand where they see their competencies.

From there, you can identify those opportunities to upskill or really, really understand what it takes to get to that level of upskill, building those internal experts and then empowering those experts to build a community. I think that that’s a pretty powerful and motivating approach because it really shows you putting the worker at the center of this, which I think is great. Paula, what I liked about you is that it’s a very realistic and pragmatic approach. In some cases, the best solution for you is to build this experience and this know-how and this expertise internally.

In some cases, especially if there’s, let’s say, a timeline that you have to meet, it might make more sense to hire from outside, to contract, depending on what that service is, and bring in external experts to help accomplish these goals. In either case, you’re still setting up the organization to accomplish these goals with different people in the workforce. I think what it highlights here is that there are a lot of options and there’s an opportunity to creatively solve the problems that we might be facing. Now, I would love to talk a little bit about results. I’m curious to hear from both of you, what business results have you observed through you’re focused on upskilling or rescaling your workforce?

[00:15:13] Paula: Thanks, Josh. People are applying what they’ve learned right across all our targeted innovation areas and across multiple projects, it’s really great. We’ve had many survey results that tell us the impact the learners are having, really positive. We haven’t quantified those or traced them to actual business results aside from measuring the time to deployment or the results of the deployment. There’s not a direct causation to learning but one could correlate that upscaling or rescaling plays a major role in the on-time delivery of new technology or process.

[00:15:47] Anthony: Now, on our side in terms of results, we started our transformation program four years ago with 10 sites. We use it as the first 10 sites to create the first framework for our smart factories. Now, we knew that a key element for us was to grow or scale but once you have your first framework, what do you need to do grow or scale? You need people and you need people acting and skilled to be able to deploy your framework which was embedding software, IoT, analytics, automations and so on. Basically, the results for us of upskilling is our capacity to address to the 100 sites.

From the first 10, we added the additional 90 for trainings through exposures, through learnings, we created some learning expedition, we created a lot of sessions for Intel-sized sharing. We expose people to new technologies and new solutions. This is for us really what allow us to address 100 sites. In terms of business results, I’ll give you some examples. The impact that we have today is that we are able to duplicate from one site to another. We have production lines today where we are able to reach close to zero-defect through technology which were not available before.

A simple example, visual inspection. You can have the best skills workers that you want, if you still have some products that require visual inspection, you will never reach your persons and you will never reach zero-defect.

Having some people able to design an AI system to work with a startup and to deploy this AI system using deep learning, you can reach zero defects. That’s the kind of impact that we have. Now, on something much more basic. We had a lot of sites, we had a startup performance system but we had a variety of way of working. We have created one through some software, some solutions that help us to manage the workflows, the work orders, the performance management and so on.

Today, we have one deployed already in 100 sites which was not available before. In fact, we trained intensively the frontline workers to use these solutions to make sure that we have the right level of adoption. This is really a before and after for us because now we know that we have a core digital model in one of our sites which is accepted by the workers because we invested on training, understanding of the processes, understanding of the application.

[00:18:20] Josh: Hey, we’re going to take a real quick break to hear from our sponsors. Stay tuned for more Conquering Chaos.

[00:18:27] Rob: Hey listeners, it’s Rob. I’m one of the producers on Conquering Chaos. I’m right here with you for every episode, working behind the scenes to make sure everything is just right for your listening experience. Whether you’re a new listener, bingeing content to help you conquer the everyday chaos, or a dedicated fan tuning in for each new episode, there’s one thing to always keep in mind, information is useless unless you use it. Obvious, right? It’s so easy to learn, forget, and then miss out on the opportunity to make real improvements to day-to-day activities.

The folks at Parsable have an opportunity for you to learn, experience and make real improvements to those same day-to-day activities. Get rid of paper on the factory floor. It’s the quickest and easiest way to make a measurable impact on safety, quality, and production. Think about it, paper-based checklists, forms and SOPs isolate workers from getting the information they need when they need it which leads to a number of inherent inefficiencies that you probably accept as a part of your own everyday chaos.

As a result, you can’t respond quickly to problems, you struggle to standardize the completion of critical tasks and you miss out on new continuous improvement opportunities. Parsable is proven to help across a number of different functions, including autonomous maintenance, line changeovers, in-process quality checks and more, which has helped industry-leading manufacturers reduce unplanned downtime, increase OEE, improve throughput, and more. See for yourself how easy it is to bring a connected digital experience to your frontline workers by using Parsable risk-free for 30 days. Check the show notes for the link. All right, back to the show.

[00:20:37] Josh: On one hand, Paula, with what you called out– while you may not have a specific ROI tied to it, there is a bit of an understanding that if this doesn’t happen, you won’t be able to produce. I think that that’s what a lot of manufacturers are facing. If you can’t bring people in, if you can’t help them get the skills that are needed to be successful, that’s going to impact what you’re actually able to produce. It’s not so much a need to focus on the return on investment right here, right now. It’s a need to get on the same page that this is the future and without it, there’s no point discussing ROI because the real ROI is we can continue being a company at the end of the day.

Then, Anthony, I like what you called out, which is look, when we look at the ability for people to successfully work with some of these advanced technologies, like IoT and AI, here’s a practical example, getting to zero defects. You’re right. Visual inspections, as “standard” as they are still rely on a significant amount of subjectivity and expertise. That varies per person, especially when we start talking about the skills and experience gaps. How can you really empower people to leverage these technologies, to increase the standardization of the results so increasing or improving the output, I should say.

Then like you called out, once you’ve got that put together, you can take that to other sites doing it this way, with this experience, with this level of expertise shared across a workforce, which goes a long way and then in that cycle of upskilling at that point. Now, switching gears a little bit, we were talking a little bit about upskilling with the current workforce. One of the big problems is recruiting. I’d be curious to hear from both of you, how have you adapted your recruitment to bridge the skills gap?

[00:22:38] Paula: Yes, so we’ve made a major investment in talent acquisition for data and analytics to help with the need for that Industry 4.0. In most other cases, we’re upskilling our current talent. We’re growing partnerships with our recruitment schools and universities to help influence curricula so that as we hire new young talent in, they will have the necessary skills that we need. We do this then by having our internal expertise work with the lecturers of our target courses and help shape the course content to ensure it meets our needs.

[00:23:14] Anthony: I have very, very similar focus to what Paula just mentioned. We also had to probably address new universities and new schools, which were probably not partners before. We are in supply chain, we are in manufacturing, we have a lot of engineers. You need statistician, you need people who are very deep in analytics, in data management, in network, in architectures and solutions. These are probably new recruitments. Now, what you see also is that we are a large group and the supply chain there is probably yes, like two-third of the employees of Schneider all working in supply chain, but we have around us some people in IT, in digital working with our customers as well.

We are also self-promoting the supply chain internally to attract people from other divisions. We may have a digital skill set currently apply to another domain, not to manufacturing, but that can be transferred in supply chain. This is also what we are looking for and obviously looking externally. Now one thing, when you speak about recruitment, digital is probably a way to make manufacturing in the industry much more attractive. I see some people that we recruited out of university who are now on the shop floor. They are highly competent in AI, machine learning and so on, but they are to be on the shop floor, they speak with some product experts.

There are a dozen of use cases, very concrete on their hand, and they have production line in front of them and they need to solve issues with AI and ML. We see a lot of guys getting super excited, like being on the shop floor, seeing the impact of what they are developing. It’s not something which is lot somewhere on the website, or they can really touch and feel the change that they’re doing. I do believe that in our recruitment, the emphasize on digital is really a way for us to show that there is something different and that manufacturing is not what you see anymore.

[00:25:18] Josh: Great call-outs on both sides and it echoes some similar thoughts that we’ve heard in previous episodes. For example, Paula one of the things that you called out is the partnerships with schools and universities, and that’s critical. Especially when it comes to exposing the younger generations to manufacturing prior to this point in their lives, where they have to make a career decision about, “What am I going to pursue? What do I like to do?” One of our previous guests, his name was Greg Chamberlain.

He talked about the importance of basically building a talent supply chain locally by partnering with different schools. It goes into a little bit of what Anthony, what you were talking about that helps dispel notions, that people have, the perceptions that people have about what manufacturing looks like because when polled, people still have a perception of manufacturing, that it is dark, dirty, dangerous. I think those are the three Ds that are typically used. That early exposure in highlighting those tools and capabilities, Anthony, that you’re calling out helps to drive awareness that that perception’s just not the case anymore.

Now, I also like what you brought up about how recruitment is not necessarily an external application. There’s a need to look at what is the talent that we currently have, even whether or not they’re actually in manufacturing operations at that point, because there could be people at the company who could bring this technical skillset and this passion and fascination for the creation in the development of the products in a way that might not be as easily identifiable when searching externally. I think that that’s a good call out too, is that you’ve already got a talent pool within the company.

There’s fun career experiences to be had by offering people the ability to try something new and apply their expertise that they’ve gained through a completely different path focused on a particular problem in front of them. I think that that’s a really interesting call out. Now, part of the conversation with upskilling or bringing in new talent and this is something that was brought up earlier. Part of that is culture and just like how there’s a big focus on continuous improvement with upskilling and the advancement of technologies and addressing skills gap.

There has to be a culture of continuous learning. I’d love to hear from both of you. How do you build the culture of continuous learning?

[00:27:48] Paula: A great question, Josh. In Johnson & Johnson, we do this in a few different ways. For example, from leadership, setting the example. We have leaders, who’s Zoom backgrounds for team meetings shows what level they have attained in their upskilling program. Setting that example, that learning is for everyone. We create learning journeys that help learners see a path and see how their learning is connected to the business needs and delivering results. We engage in leaders to have active support of their learners and we also create democratized learning experiences.

[00:28:28] Anthony: We have a motto in Schneider, which is, “What did you learn today?” Every day you should learn something. Things are moving so fast. You are meeting people. You need to be curious about what’s happening around you. Now we realize that we are all online now. We are all remote and you may learn from someone with very far from you, in another timezone. We are moving to what microlearnings, for instance, which are curated for your profile. We have, for instance, the platforms that you are using internally, that help us to collect all these microlearning that may be videos, webcast documents, and so on, which are really tailored for your profile.

One thing as well is that every digital transformation leader has under his own responsibilities the creation of the learnings require to be successful. Me and my team, we had to create the learnings at the same time as we were delivering the solutions for the digital transformation. It’s really a key element. Meaning, you cannot consider that you are deploying something if you don’t run people. This part is sometimes skipped. In all our factories also, our learning academy with the different managers and leaders that created digital learning corners. On the shop floor– because learning is becoming digital and learning should be accessible on your hand.

We have digital learnings corners available to all our workers where they can have access. More and more we are tailoring also what we are delivering in terms of learnings. There is obviously some standard information around, how do you operate, our procedures, the evolutions of our performance system, but we make it so accessible, let’s say the latest learning on the latest technologies that we are delivering, the evolution of the system. A basic thing, when you have software, you may have an update every two weeks, every month, every two months, how do you make sure that people know what you are delivering?

This is why you need to decentralize the learning and breaking as close as possible to the people. We are even working on making it accessible to everyone’s mobile phone, even if you are not completely involved in our network, which is something we are working on. Really, decentralizing the learning, bringing it as close as possible to everyone. Micro learnings, because we don’t spend anymore two, three hours learning about software. You need to be able to fix that in your agenda. Especially when you are on the shop floor, meaning you need to balance production, delivering, and learning. We have the ambition to have minimum 10 hours of learning for everyone and every year. That’s something we are very committed to.

[00:31:24] Josh: I think those are great. Paula, what I loved about what you called out is the example and the visibility by leadership, that idea of at all times, you can see what I’m focused on and what level that is. That idea of transparency, I think really sets a good tone of encouraging. I’ve done a lot of training in my time across a variety of different subjects, both received and been the one conducting the training, and I think people can sometimes get a little shy or a little bit embarrassed about their progress, and so being humble and vulnerable and saying, “Look, I’m learning too.” I think really goes a long way in encouraging people to be honest about what they need to focus on and feel empowered to do that.

Then that idea, Anthony, that you brought up of micro learnings, making this information not only accessible but in a format that’s easy to consume, and shorter to consume is critical because everyone has a different learning style, and more and more that learning style is visual, and it’s shortened to the point. Now let’s talk a little bit about career paths. Let’s talk about these career paths. How do you adapt your career path for digital profiles?

[00:32:45] Anthony: Our carrier paths are becoming much more transversal. What we see either within our supply chain or across Schneider, as I said earlier, you may have competencies on IoT, on analytics, on networks that can be applicable in really different domains. I’m recruiting, for instance, today, some people who don’t have a background in manufacturing at all, but in fact, they have a strong background in software management and software deployment and adoption. This is a skill set that I need. You see that person in digital can become horizontal, so that’s really interesting.

Obviously, you can have still the vertical evolutions because things are getting complex, and we need people with the right vision. I already see that as an opportunity. Now, people need to reflect about– We speak about different profiles or some people will speak about T Profile. Some people we speak about the age profile, you have a double skillset for you to decide. I like people who have one or two domains of expertise and show that they can combine it with another domain of expertise to build something different.

We need to open our skills path here and really to allow people to bring to another department, to another workstream, another part of the supply chain, their skills, which are still on digital, but we augment your activity, accepting probably your first period of three, six months of learning on the core business skills.

[00:34:17] Paula: We’ve identified our needed core skills and capabilities for our staff to be successful in the future working environment, and I guess over time, new jobs would be created that have different pathways for careers, but we are building on our current profiles, not starting from scratch, at least not for now.

[00:34:35] Josh: With career paths. Those are incredibly important for younger workers. Study after study show that Millennials, Gen Z, want to know what the point is, what the why is, what am I working towards and what am I progressing towards? Having that idea of what a career could look like is critical, and even just that recruitment side of things, and that retaining side of things like, “Here’s what you can work towards.” Anthony, I love what you called out because it echoes some of the topics that we just covered, which is you don’t necessarily have to have the manufacturing experience.

These digital technical skills that you have, you can take that and teach someone what they need to know about manufacturing, bring them into that manufacturing domain and let them apply those skills to solve those problems, thus building that manufacturing expertise while capitalizing on that digital experience. When you look at that, that’s really starting to create a totally new role at that point, which is also important to think about, which echoes Paula, what you were talking about, over time, this is creating a new career path. We’re in this exciting opportunity for people to almost build what a modern-day career looks like in manufacturing.

With this period of innovation, it’s almost like there’s new exploration needed to really define what that experience looks like. Now, I want to wrap up with a final question because these are all great topics, and discussions that we’re having, but whenever you’re thinking about how to change a process or change an approach or innovate, you have to think about, is this sustainable? My final question to both of you is how do you sustainably embed the process of upskilling within your business?

[00:36:32] Paula: So important, sustainability. We’re continuously scanning our business to detect the current and the unmet needs. We keep learning connected to the business strategy and our digital and technology roadmaps. We also connect self-reflection and self-assessment of our current skills and our people’s current skills to understand what skills are needed to do the work at hand. Having good internal processes and external partners, who can provide the content and experiences that will push the learners beyond today’s knowledge and into the expertise that’s needed for the future.

[00:37:11] Anthony: A couple of things on our side. Now we have very regular touch points between managers and employees and workers to making sure that we are addressing the different skills gap that may be detected, and these are things that we do all along the year. We have also what we call our stem of reference, which is really our reference shows in terms of skill sets and what we are expecting from everyone. This is really something that helps us every two, three years, to review where we are and where do we want to go in terms of skill sets. You have some skills that disappear because either you don’t them anymore, or either it’s a new skill that everybody already master.

That’s interesting because we have this rotation and we have been this sculpture of reviewing this competency framework every two, three years, to update our own visions on a regular basis.

[00:38:07] Josh: Really, what I’m hearing is an aspect of accountability. If you want to implement this, you have to monitor it. You have to check-in, “Are we accomplishing what we’re trying to accomplish? Where the gaps, where the struggles, what need to do to fix that?” Ultimately, that’s what’s going to drive that sustainability is that, that accountability, it’s going to last, the longer that you’re focused on it, everyone’s bought in that this is a priority. We have to check it, we have to discuss it. We have to address it. We have to do something about it. That’s what’s going to keep it going, and that’s ultimately how to sustain.

Well, I think this has been a great conversation. I want to thank both of you for your time, and for sharing your expertise and your experience. I think too often and what I’m going to call out is the purpose of this show, is there’s a lot of information out there that comes from thought leaders, consulting companies, people who are thinking about the future, but there’s not enough testimonials and discussions from people who are actually living and breathing and dealing with these problems.

It is so great to be able to bring you on and share your expertise and your experiences with a broader community. I know that that’s something that people can take away and learn from and think about, and ultimately be successful with the things that have made you successful. Again, really appreciate your time. Look, for our listeners to learn more about the NGIL, check the show notes for a link to the website, or then there’s also the contact information on the website. You can send an email to new-gin_industry@weforum.org. You could check the show notes for that link as well.

Paula, Anthony, thank you so much for being here today.

[00:40:01] Anthony: Thank you, Josh.

[00:40:02] Paula: Thanks, Josh. It was great.

[00:40:07] Walter: Hey all. It’s Walter. I’m another producer for Conquering Chaos. Before you go, if you’re not ready to try Parsable to help you get rid of paper, why not watch a quick video instead? Check the show notes for a link to a demonstration Josh put together to show frontline workers what it’s like to use a dynamic digital experience to get work done. In it, Josh shows you how using a modern-day app enables you to connect to people, information, systems, and machines just like the apps you use in your personal lives. Take a look and let us know what you think.

[00:40:42] Josh: That’s the show. Thank you so, so much for joining us today. Conquering Chaos is brought to you by Parsable. If you’re a fan of these conversations, subscribe to the show and leave us a rating on Apple Podcasts. Just tap the number of stars you think the show deserves. As always, feel free to share what’s top of mind for you and who you think we should talk to next. Until then. Talk soon, take care, stay safe, and bye-bye.

Listen to find out how manufacturer leaders are building the next generation of industrial leaders