Root Cause Analysis (RCA): How Technology Can Help

What is Root Cause Analysis (RCA)?

Root Cause Analysis (RCA) is the process of finding the underlying source of a problem, so that a solution can be identified and implemented. It’s an approach to problem solving that uses data analysis, discussion and tools to dive into the symptoms of a problem to uncover the underlying issue. It doesn’t boil down to uncovering any old contributing factor, but the true underlying cause of an issue so that it can be prevented from occurring again.

When a problem occurs within your manufacturing operations, your number one priority is to fix the issue and bring everything back to normal. At the same time, you also want to figure out why the problem occurred in the first place, in order to prevent it from recurring.

There are several reasons why a problem could occur. Maybe there was a material or equipment failure, an inefficient work process, lack of visibility into an organizational process, inappropriate adherence to standard operating procedures (SOPs) or a system failure.

Unfortunately, root cause analysis is more of a reactive approach, which means an error or problem event has already occurred. Within your manufacturing organization root cause analysis, problem solving and incident investigation are understood by answering three simple questions:

- What was the problem?

- Why did it happen?

- What can be done to prevent it from happening again?

History of Root Cause Analysis

Root cause analysis is tied to the idea of total quality management (TQM) and continuous improvement. TQM has developed in different directions which include problem analysis, problem solving and root cause analysis.

Root cause analysis is an important part of continuous improvement. On its own, root cause analysis won’t produce any results, but must be part of a larger problem solving culture for quality improvement.

Goals of Root Cause Analysis

- The first goal of root cause analysis is to identify the root cause of an issue.

- The second goal is to understand how to fix or learn from the underlying problem within the root cause.

- Once you’ve identified and eliminated or controlled the root cause, you need to set up systems and/or processes to avoid a recurrence.

Beyond identifying where processes or systems failed that caused the issue, it’s important to pay attention to the third goal.

Your analysis is only as good as what you do with that information.

Instead of just treating the symptom of the problem, you can use root cause analysis to adjust operating procedures and systems issues to prevent future problems from popping up.

Root Cause Analysis Tools and Methods

Root cause analysis can be applied using a variety of tools and strategies. Here are the most common and widely used techniques.

5 Whys

The 5 Whys technique is part of the Toyota Production System, developed by Sakichi Toyoda and the technique became an integral part of the Lean philosophy. “The basis of Toyota’s scientific approach is to ask why five times whenever we find a problem…By repeating why five times, the nature of the problem as well as its solution becomes clear.“

When using this technique, for every answer to a “why” question you will want to follow up with an additional “Ok, but why?” question. The common practice is to ask why questions five times which will lead you to the root cause – but there’s no limit to how many “whys” you can ask.

Here is an example of applying the 5 Whys. Let’s say your production line isn’t applying the label correctly to a bottle. This isn’t only affecting the quality of your product but it’s causing significant waste. The problem statement can be, “The label has a wrinkle in the middle of the bottle.”

First why: Why isn’t the label being applied properly to the bottle?

First answer: Because there’s something wrong with the machine.

Second why: Why is there something wrong with the machine?

Second answer: Because a part or component of the labelling arm is loose.

Third why: Why is the part loose?

Third answer: Because the component wasn’t inspected correctly.

Fourth why: Why wasn’t it inspected properly?

Fourth answer: Because the line operator didn’t carry out all of the clean/inspect/lubricate (CIL) steps correctly.

Fifth why: Why didn’t the line operator carry out all the CIL steps correctly?

Fifth answer: Because they’re going off their memory of the CIL steps.

An important thing to note when carrying out the 5 whys, while it might be tempting you don’t want to jump into the solution. The solution comes after uncovering the root cause(s).

There you have it. After five questions you discover the root cause of why the label isn’t being applied correctly. By finding answers to each consecutive question, ultimately the final “why” will lead to the failure and you can take steps to address the problem.

Fishbone Diagram

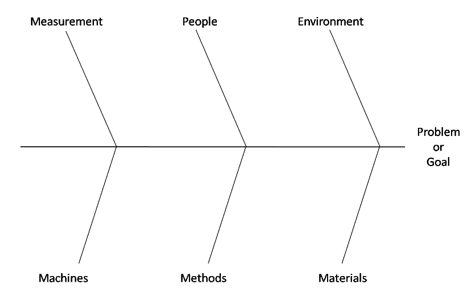

The fishbone diagram, also known as Ishikawa or the cause-and-effect diagram, is another commonly used tool in root cause analysis. It’s used to identify possible causes for a problem that led to the current effect. In this instance, you group potential causes of the problem into subcategories linking them back to the main problem, until you end up at the right one.

You would begin with the problem (the spine of the fish skeleton) and then come up with several categories of causes that are branches from the main line (the bones of the fish skeleton). These categories include things like: people, environment, method, material, measurement and machine. After coming up with your categories, you then drill down further. For example, under “machine” you might consider root cause factors like: machine malfunction, employee’s fault or a machine defect.

The next step is to dig deeper into each branch (or bone) in order to get closer to the root cause of the issue.

Pareto Chart

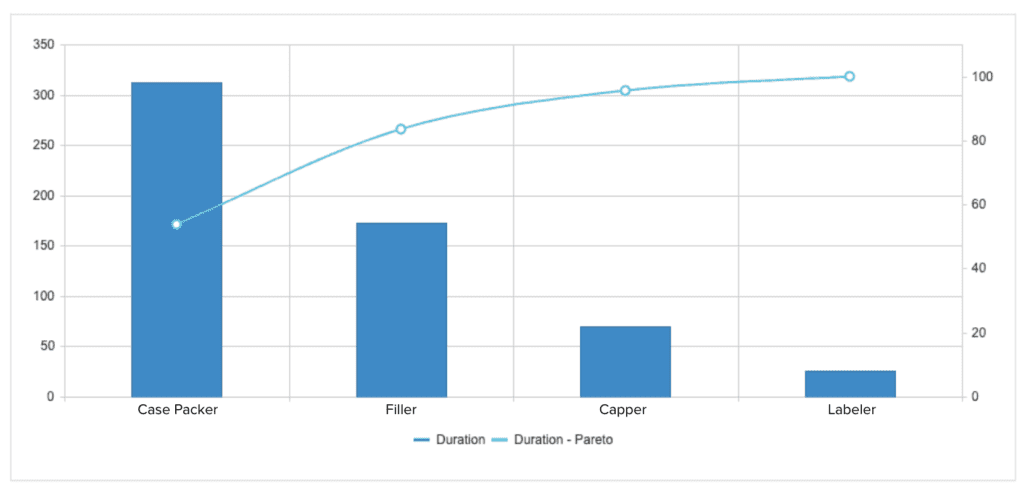

A pareto chart is a bar graph that shows which factors are most significant. It’s based on the Pareto Principle (80/20 rule) that states 80% of problems arise from 20% of the failure modes. Within the bar chart the height of each bar represents the quantity of a cause, sorted from the greatest impact to the least impact (from left to right). This creates a clear visualization of information, allowing you to identify where to invest your brainstorming efforts and actions to address the issue. The bars in the graph below represent the amount of time spent at each machine, while the line shows the cumulative time. You can validate that if you solve for the largest bar and you will impact a large part of the total problem.

A pareto chart is typically used during a brainstorm session to show the contribution of each of the items or root causes of a problem. They can be effective, but are only useful with certain types of data – hypothetical data.

Scatter Plot Diagram

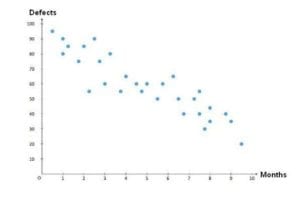

A scatter plot or scatter diagram is a way of identifying if there’s a relationship between two sets of data. It’s a quantitative method for determining whether two variables are correlated, like testing potential causes identified in your fishbone diagram.

To create a scatter diagram, you plot your independent variable (or your suspected cause) on the x-axis and your dependent variable (the effect) on the y-axis. If the pattern shows a line or curve, you can easily tell that the variables are correlated and you can continue with a regression or correlation analysis.

Failure Mode and Effects Analysis (FMEA)

Failure mode and effects analysis (FMEA) is an approach used to identify all the potential failures in a design, manufacturing process, assembly process, product or service. It includes two main components: Failure modes and effects analysis.

Failure modes include different ways, or modes in which something might fail. Failures are any errors or defects, especially ones that affect the customer. Effects analysis involves looking at the consequences of those failures.

Root Cause Analysis: How Technology Can Help

Let’s go back to our previous example, where your production line isn’t applying the label correctly to the bottle. Beyond identifying the cause of the issue, what role can technology play to help prevent this from happening in the future?

Adopting a solution like Connected Worker® by Parsable can help drive compliance, consistency in the way CIL is carried out, provide access to powerful data and help drive improvements among your team. Let’s dive into this further.

If you’re still relying on paper-based processes, in this case, when an issue arises someone from your team would enter that into a database or system of record. Then, the report would be sent to a manager or compliance lead for review. A team member would then perform a root cause analysis to understand the problem. Think of all the time that’s wasted.

In this situation, it’s likely that your overall equipment effectiveness (OEE), the percentage of planned production time that is truly productive, is low. This could be because you have a lot of unplanned downtime (check out these interesting stats on downtime) or it’s a quality issue. Maybe your machine is from 1947, it’s old and needs more frequent CIL. How do you know if your team is carrying out CIL frequently enough to prevent these unplanned shutdowns? It could be an old machine that still runs steady, similar to an old car that just needs more oil changes.

Perhaps, the process is not being followed because workers are relying on their memories, which led to the machine issue in the first place.

With Connected Worker, once you’ve identified the root cause, you can digitally document the CIL process and make it available to your operators on a mobile device.

They now have a clear understanding of how to perform CIL correctly, and don’t need to rely on their memory or institutional, or tribal, knowledge. You now have visibility into what is being done, the quality of the CIL carried out by your team, and you have data into how often CIL is taking place.

You will be able to drive completion rates, compliance and consistency by holding everybody accountable on executing the important routines that will enable your operation to excel. With the visibility you obtain, you can make the system or process work for your operation instead of your operation working for the system.

Connected Worker enables workers to easily capture the data to understand the “why” that leads to the real root cause. Once you’ve identified the issue, the next step is to implement a solution that will help incrementally drive continuous improvement.