The Ultimate Guide: Connected Worker Software

The manufacturing industry has long been a driving force for economic growth, job creation, and productivity. However, as the world becomes increasingly digitized and interconnected, the manufacturing landscape has evolved dramatically. Harnessing digital technologies, companies can now tap into previously untapped efficiencies and streamline their operations in ways that were never conceivable before.

One of the key innovations in this space is the Connected Worker Platform, which allows workers to access real-time data, empowering them to make better decisions and execute tasks with greater precision. In this blog post, we will delve deeper into the concept of Connected Worker Solutions and explore how they have the potential to transform manufacturing processes and operations significantly.

The Connected Worker: Taking Manufacturing and Operations to the Next Level

A connected worker solution is an integrated approach that harnesses IoT sensors and mobile devices, creating a seamless and integrated work environment. Offering workers instantaneous access to valuable information and resources in real-time, this technology has the potential to improve their productivity, safety, and collaboration significantly.

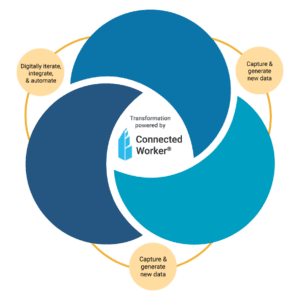

At the heart of this technology is the Connected Worker Platform, which is the central hub that collects, analyzes, and shares essential data throughout an organization. In short, it’s the foundation upon which businesses can digitally transform their manufacturing and operational processes.

What is a Connected Worker Solution?

Connected worker solutions refer to software applications designed to empower employees with instant access to critical company information, tools, and resources. This encompasses job instructions, safety protocols, training materials, and communication tools that can be accessed remotely and in real time. Connective worker solutions aim to improve employee productivity, safety, and collaboration by enabling timely access to essential data. Moreover, these platforms facilitate data collection and monitoring of worker activities, thereby contributing to more informed decision-making and continuous improvement of operations.

As the Internet of Things (IoT) technology advances, IoT sensors have become an integral part of connected worker solutions, providing valuable insights into equipment, processes, and personnel. In addition, IoT sensors offer real-time monitoring of various parameters, such as temperature, pressure, vibration, and more, allowing for preventive maintenance and performance optimization across the operation.

Connected Worker Platforms: The Digital Backbone

Fundamentally, connected worker platforms are digital ecosystems that intertwine various connected worker technologies to create an innovative, efficient, and responsive work environment. Typical features found in these software applications may include:

- Remote access to job instructions

- Real-time safety updates and alerts

- Access to training materials

- Communication tools for better collaboration

The primary aim of these platforms is to ensure that workers have the right information at the right time, regardless of location. This empowers them to make informed decisions and enables the collection of valuable data, which can be used to monitor and evaluate their performance and productivity.

Connected Worker in Manufacturing: The Perfect Fit

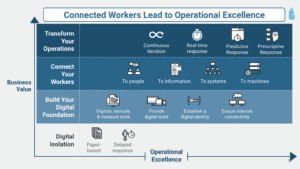

By its very nature, manufacturing is a highly complex and competitive industry. To succeed, companies must optimize their production lines, minimize downtime, and ensure product quality while controlling costs. Connected Worker Solutions are designed to address these challenges, with unique benefits tailored to the manufacturing sector.

Why Manufacturing Needs Connected Worker Solutions

Here are the main reasons why manufacturing is perfectly suited to benefit from Connected Worker Solutions:

- Increased productivity: By providing real-time access to critical information, connected worker solutions empower employees to complete tasks more efficiently, directly boosting overall productivity.

- Improved safety: In work environments where safety is paramount, real-time safety updates and alerts can significantly reduce the risk of accidents and injuries.

- Enhanced collaboration: Remote communication and collaboration tools connect workers, departments, and even facilities, resulting in smoother operations and faster problem resolution.

- Data-driven decisions: As connected worker platforms gather and analyze large amounts of operational data, businesses can leverage this information to make data-driven decisions and further optimize their processes.

How Connected Worker Solutions Address Manufacturing Challenges

Connected worker platforms have become increasingly popular due to their potential to address several challenges the manufacturing sector faces. These platforms aim to improve safety, quality, productivity, and maintenance throughout operations by leveraging IoT sensors and other connected worker technologies. In addition, connected worker solutions can streamline logistics and enhance decision-making processes.

Here are some of the ways connected worker solutions can address manufacturing challenges:

Streamlining Communication and Collaboration

Effective communication and collaboration are paramount to a well-functioning manufacturing operation. Connected worker platforms facilitate seamless interaction between teams, supervisors, and remote workers. This real-time communication enables prompt decision-making and swift problem resolution and fosters a stronger team spirit. Furthermore, video calls and augmented reality can enhance remote assistance, making it easier for teams to collaborate from anywhere.

Enhancing Safety Protocols

Safety is a top priority in the manufacturing sector. Connected worker platforms ensure that employees are aware of safety hazards and have access to the latest safety information at any given moment. IoT sensors can detect anomalies indicating danger, such as high temperatures or gas leaks, and send instant alerts to responsible personnel to initiate corrective action. This early detection and intervention can significantly reduce the risks associated with workplace accidents.

Optimizing Productivity

Connected worker solutions can streamline various processes, helping businesses to eliminate bottlenecks and increase efficiency. Real-time data gathering and analytics and insights empower decision-makers to identify performance gaps and address them proactively. Adopting technology like automation and artificial intelligence can enhance productivity and ensure resources are optimally utilized.

Bolstering Maintenance and Asset Management

Proper equipment maintenance is crucial in preventing costly downtime and ensuring optimal performance. IoT sensors integrated within connected worker platforms can collect critical information on machinery functioning, which helps detect signs of wear and tear. By leveraging predictive maintenance analytics, businesses can proactively schedule maintenance activities to minimize disruptions and extend equipment life.

Improving Logistics and Supply Chain Management

The world of logistics and supply chain management is a complex and ever-evolving machine. One of the biggest challenges in this industry is keeping up with the demand for real-time information. That’s where connected worker solutions come in. By leveraging the latest Internet of Things (IoT) technology, businesses can improve their communication, monitoring, and analysis capabilities. From tracking inventory and shipments to monitoring workers’ progress and safety, these innovative tools provide insight that was once impossible.

This leads to increased efficiency and productivity and can help businesses reduce waste, optimize their operations, and provide better customer service. If you’re looking for ways to stay ahead of the competition in logistics and supply chain management, connected worker solutions are the way to go.

Digitize Your Frontline

Optimizing your frontline operations for manufacturing and industrial businesses can determine your success or failure. Parsable provides a solution to track, trend, and optimize the inefficiencies that impact your operational results. Our software enables collaboration amongst your teams to identify and fix issues. The insights you gain from Parsable help you engage your workforce and achieve impressive results by continuously improving safety, quality, productivity, maintenance, and logistics throughout your operations. Don’t let what you don’t know hurt your business. Transform your operations with Parsable today.

Ready to revolutionize your operational workflows? Experience the power of Parsable’s Connected Worker® software firsthand. Schedule a demo today and discover how our solution can streamline your operations by digitizing your frontline.