Forklift Safety: 7 Simple Tips

Forklifts or lift trucks, also known as powered industrial trucks, are one of the most commonly used pieces of equipment on worksites and in warehouses. They are powerful tools and there’s a higher chance of sudden accidents, especially when an operator doesn’t have proper forklift safety training. Why is forklift safety important? And, how can your team minimize fatalities and serious injuries? The answer lies with training.

Forklift Accident and Injury Statistics

The Occupational Health and Safety Administration (OSHA) estimates there are around 1.5 million workers in the U.S. who operate over 855,900 powered industrial trucks. According to OSHA, forklift accidents cause around 35,000 serious injuries and 62,000 non-serious injuries every year.

The number one cause of forklift related work fatalities is pedestrians being struck by the vehicle, and the second leading fatal event is when forklifts tip over. According to the Bureau of Labor Statistics, in the past decade, more than 600 workers have lost their lives due to forklift related incidents. Studies have shown that more operator training and retraining for forklift operational procedures could reduce accidents by 70 percent.

With any piece of machinery there’s always risk involved. Not only is it essential to ensure your workers are trained on the appropriate safety measures, but it’s important that they brush up on that training. Here are some essential tips for forklift safety.

7 Tips for Forklift Safety

1. Proper Forklift Training

Since as we just mentioned accidents are caused by poor training, it’s critical that any worker operating a forklift is trained and licensed in accordance with OSHA standards.

2. Operate at a Safe Speed and Use the Horn

With the number one cause of forklift fatalities due to pedestrians being hit, it’s important to operate forklifts at a safe speed and use the horn at blind intersections and corners. Sound your horn to alert pedestrians or other forklift operators nearby that you’re approaching. And make sure you take corners and turns slowly in order to avoid the risk of tipping over.

3. Wear a Seatbelt

If you’re in a moving vehicle you should always wear a seatbelt. This may sound like a no-brainer, but it applies to forklifts too. Always wear a seatbelt when operating a sit-down forklift.

4. Wear Proper Clothing

When working in a warehouse or worksite it’s important that forklift operators wear the appropriate personal protective equipment (PPE), including hard hats, protective footwear and high-visibility clothing.

5. Forklift Inspections

Before each shift you’ll want to inspect the forklift to ensure it’s in proper working condition and free from any safety hazards before you begin to operate it. Some recommended daily checks include:

- Look for potential hazards

- Check for oil, water or radiator leaks

- Examine mast and overhead guard for damage

- Check the tire pressure and fluid levels

- Ensure the forks are in good working condition

- Test the brakes, horn, steering wheel and lights

6. Create a Floor Marking System

A floor marking system is a simple way to communicate with your team to increase worker safety by physically marking the floor. You can use yellow to mark physical hazards and red to show fire hazards, fire equipment and emergency switches. Place floor markings to indicate right-of-way, pedestrian-only paths and forklift only routes – to improve the flow of traffic and ultimately enforce safety.

7. Forklift Load Capacity

It’s never a good idea to exceed the weight limit of a forklift, by doing so you’re automatically putting the machine at risk of tipping over. Every machine has a certain load capacity, so make sure your forklift operators keep loads within the recommended capacity.

How to Prevent Worker Fatalities and Injuries

What can you do to minimize fatalities and workplace injuries caused by forklifts? One of the best ways to ensure worker safety is to reduce the potential for human error. Unfortunately, human error accounts for many worksite and warehouse incidents and not only does it put your whole team at risk, but oftentimes these incidents can be incredibly dangerous.

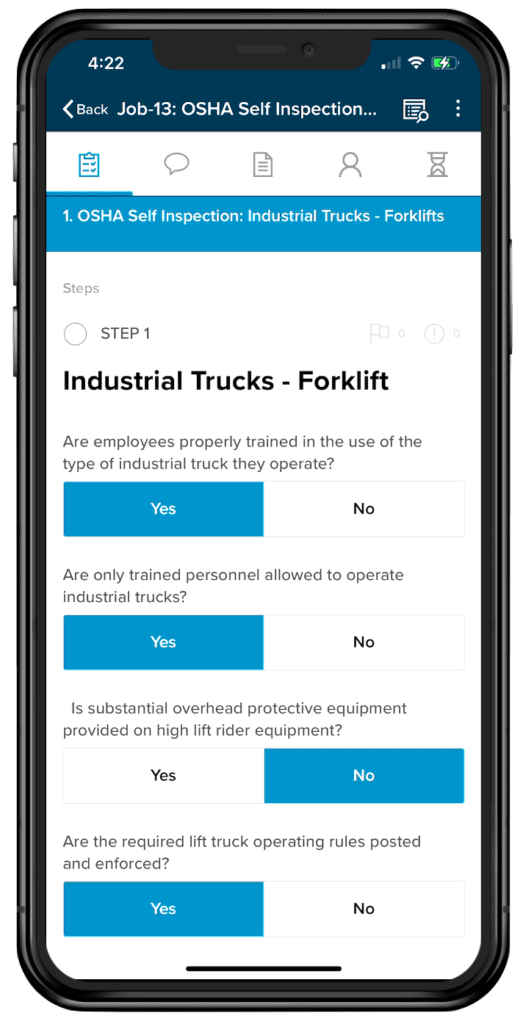

Proper training is the cornerstone of forklift safety. This is where technology comes into play. Providing your team with access to all of this information in a digital format and embedding it in their daily work execution helps ensure they consistently follow each step and minimize the risk of human error. Whether that means embedding safety steps like ensuring forklift operators are wearing the appropriate PPE, or creating a forklift inspection checklist mentioned above, this helps ensure workers follow the necessary protocols and safety steps, whether they’re a 20-year veteran on the job or a new hire.